Application of fr4 epoxy board in wind turbine

FR4 epoxy board, a classic epoxy-glass fiber laminate, plays a vital role in wind turbine electrical insulation and s...

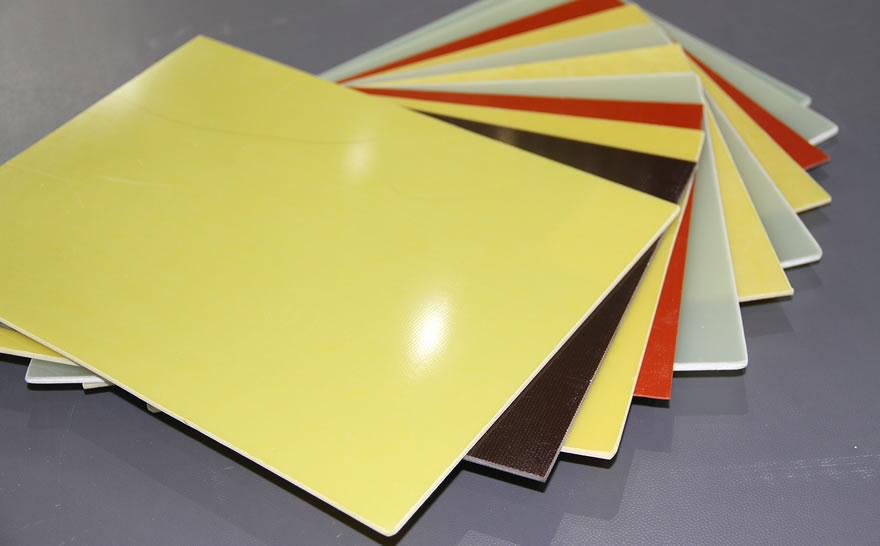

FR4 epoxy board, a classic epoxy-glass fiber laminate, plays a vital role in wind turbine electrical insulation and structural support due to its excellent electrical properties, mechanical strength, and environmental resistance.

Core Characteristics of FR4 Epoxy Board (Why Choose It?)

Before understanding its applications, it’s important to understand that wind turbines operate in extremely harsh environments:

High Voltage: Generator output voltages can reach several kilovolts, and grid connection requires high-voltage inverters.

Severe Vibration: Wind and rotating components cause constant vibration.

Large Temperature Differences: From the frigid polar regions to the scorching desert, temperatures vary greatly.

Humid Salt Spray: Offshore and coastal wind turbines face corrosive environments characterized by high humidity and salt content.

Long-Term Reliability Requirements: Design lifespans typically exceed 20 years, resulting in high maintenance costs.

FR4 material perfectly matches these requirements:

Excellent Electrical Insulation: High dielectric strength effectively isolates high voltages and prevents short circuits. Superior Mechanical Strength: High rigidity, excellent bending and impact resistance, and the ability to withstand long-term vibration without deformation or breakage.

Excellent Moisture and Chemical Resistance: The resin system maintains stable electrical and mechanical properties even in humid environments and resists salt spray corrosion.

Heat Resistance: A wide operating temperature range (typically exceeding 130°C) meets the temperature rise requirements of generator operation.

Flame Retardancy: Typically achieves UL94 V-0 rating, which is critical for preventing electrical fires.

Specific Applications in Wind Turbines

FR4 epoxy board is primarily used in the stator and rotor sections of generators, specifically including the following key components:

1. Insulating Spacers/Isolators

This is the most common and important application of FR4 in wind turbines.

Function: Used to secure and isolate the generator’s winding coils (copper busbars).

Location: Installed in the slots or ends of the stator core, reliably isolating coils at different potentials and between the coils and the grounded core. Requirements: Extremely high mechanical strength is required to withstand the electromagnetic forces and vibrations of the coils, while a high insulation level is also required to prevent high-voltage breakdown. FR4 sheet is precisely CNC-machined into various shaped spacers to perfectly meet these requirements.

2. Slot Wedges

Function: Used to compress and secure the winding coils embedded in the stator core slots, preventing them from loosening or vibrating under electromagnetic forces.

Requirements: High mechanical strength and toughness, as well as good insulation properties, are required. FR4 sheet can be processed into strip-shaped slot wedges, and its smooth surface and wear resistance also facilitate coil insertion.

3. End Support and Binding Rings

Function: At the ends of the stator windings (the portion extending from the core), the coils need to be securely supported and bound together to withstand the enormous centrifugal and electromagnetic forces.

Requirements: Large ring-shaped or bracket-like structures are required, requiring the material to possess extremely high rigidity, strength, and dimensional stability. FR4 can achieve this through lamination and processing.

4. Interphase Insulation and Partitions

Function: Used to isolate the different phases of the generator windings (e.g., U, V, and W) to prevent interphase short circuits.

Requirement: A complete insulation barrier is required. FR4 sheets are cut into specifically shaped partitions and inserted into the interphase gaps.

5. Junction Box and Control System Insulation

Function: Serves as busbar support, printed circuit board (PCB), or mounting plate in the generator’s junction box, frequency converter (inverter), and control cabinet.

Requirement: Provides structural support and electrical isolation. While thinner FR4 materials may be used, their core functions remain the same.

Comparison with Other Materials

Although other insulation materials may be used in wind turbines, FR4 offers unique advantages:

Comparison with DMD/DMC composites (polyester felt/polyester paper): DMD and other materials are primarily used in small and medium-sized general-purpose motors, but their mechanical strength and moisture resistance are generally inferior to FR4, making them less suitable for the large, high-reliability requirements of wind turbines.

Compared to laminated wood products: Laminated wood is less expensive, but its performance consistency, moisture resistance, and aging resistance are far inferior to FR4, making it obsolete in high-end applications.

Compared to high-performance composite materials (such as Nomex aramid paper): Nomex paper offers excellent heat resistance and electrical properties, but is extremely expensive. It is typically used in applications requiring extremely high thermal ratings (such as Class H and Class C insulation), while FR4 offers better cost-performance for insulation systems rated for Class F (155°C) and below.

Summary

In summary, FR4 epoxy board is a key insulation and structural material for large wind turbines, particularly their core component: the stator. While not a cutting-edge new material, its balanced combination of performance, reliability, and cost-effectiveness has secured it a solid position in the highly reliable wind power sector.

Its primary responsibilities include:

Ensuring high-voltage electrical safety: preventing breakdown and short circuits.

Ensuring mechanical structural stability: resisting electromagnetic forces and vibration, and securing the windings.

Adapting to harsh environments: withstanding temperature fluctuations, humidity, and salt spray corrosion.

It is these characteristics that ensure that wind turbines can stably “generate electricity from the wind” for more than 20 years.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations