Application of Electrical Paper Pressboard in Transformer

Electrical Paper Pressboard (commonly referred to as pressboard) is an electrical insulating material made from high-...

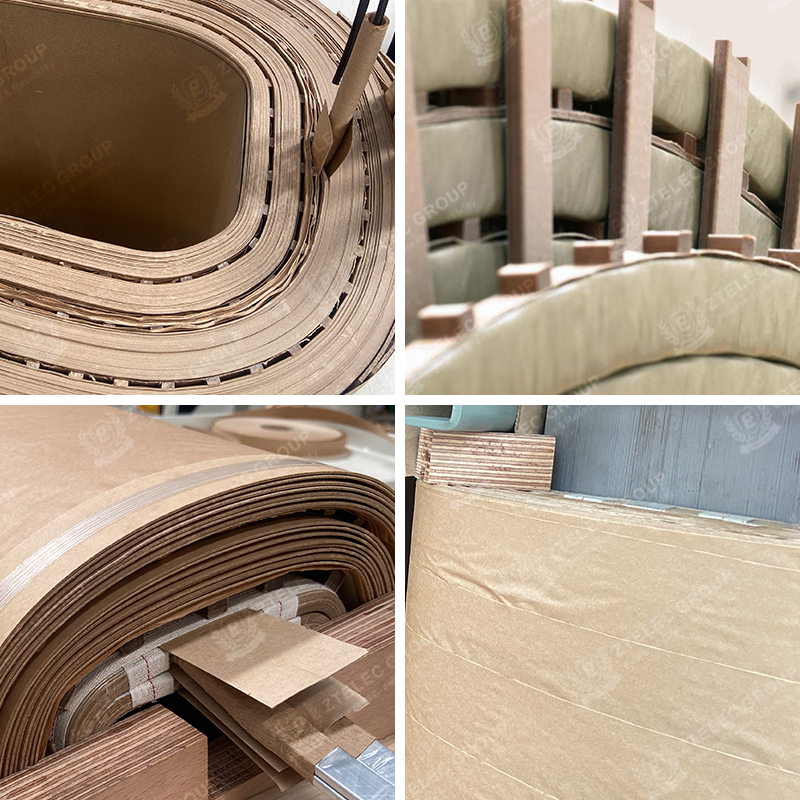

Electrical Paper Pressboard (commonly referred to as pressboard) is an electrical insulating material made from high-quality paper fibers that are compressed through a specialized process. It features excellent dielectric properties, mechanical strength, and heat resistance, and is widely used in insulation systems for various power equipment. Depending on its thickness and density, it can be classified into pressboard (thicker) and thin paper (used for winding-to-winding insulation).

Applications and Selection of Electrical Paper Pressboard in Transformers

Electrical Paper Pressboard is one of the most commonly used solid insulating materials in transformers. It is widely applied in winding-to-winding insulation, winding-to-core insulation, bushings, and structural supports.

1. Winding-to-Winding Insulation

Low-voltage windings: Thin electrical paper is used to provide layer insulation while maintaining mechanical stability of the windings.

High-voltage windings: Thick pressboard withstands high electric field strength, preventing short circuits and partial discharges.

2. Winding-to-Core Insulation

Electrical pressboard is often used as core supports, spacers, or liners, preventing direct contact between windings and the core, and improving insulation reliability.

3. Bushings and End Supports

In high-voltage bushings and end structures, pressboard serves as a structural insulating material, keeping conductors fixed and preventing displacement or vibration.

4. Oil-immersed and Dry-type Transformers

Oil-immersed transformers: Pressboard is compatible with transformer oil and maintains insulation performance over long-term immersion.

Dry-type transformers: Pressboard is used as part of epoxy resin-impregnated insulation systems, providing layer and structural insulation.

Electrical Paper Pressboard Selection Guide

Selection should consider voltage level, dielectric strength, mechanical requirements, and operating environment, mainly based on the following parameters:

Parameter Description Application Recommendation

Thickness 0.2–3.0 mm Thin paper for low-voltage layer insulation; thick pressboard for high-voltage layers and structural supports

Density 0.9–1.3 g/cm³ Higher density pressboard offers better mechanical strength, suitable for load-bearing or vibration-prone areas

Thermal Class Class A (105℃), Class E (120℃), Class B (130℃), etc. Choose according to transformer operating temperature to ensure long-term reliability

Dielectric Strength kV/mm High-voltage windings and bushings require pressboard with high dielectric strength

Compatibility With oil or resin Oil-immersed transformers require oil-compatible materials; dry-type transformers require epoxy-compatible materials

Environmental Conditions Humidity, vibration, corrosion, etc. Special environments may require moisture-proof or corrosion-resistant pressboard

Selection Recommendations

Low-voltage windings: Use thin paper; choose thermal class according to temperature rise.

High-voltage windings: Use thick pressboard with high dielectric and mechanical strength.

Core supports and structural parts: High-density, high-thermal-class pressboard to ensure structural stability.

Special environments: Moisture-proof pressboard for humid conditions; high thermal-class pressboard for high-temperature environments.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted