Application of Crepe Paper in Oil-Immersed Transformers

Introduction of Crepe Paper Crepe paper is a flexible electrical insulation material widely used in oil-immersed tra...

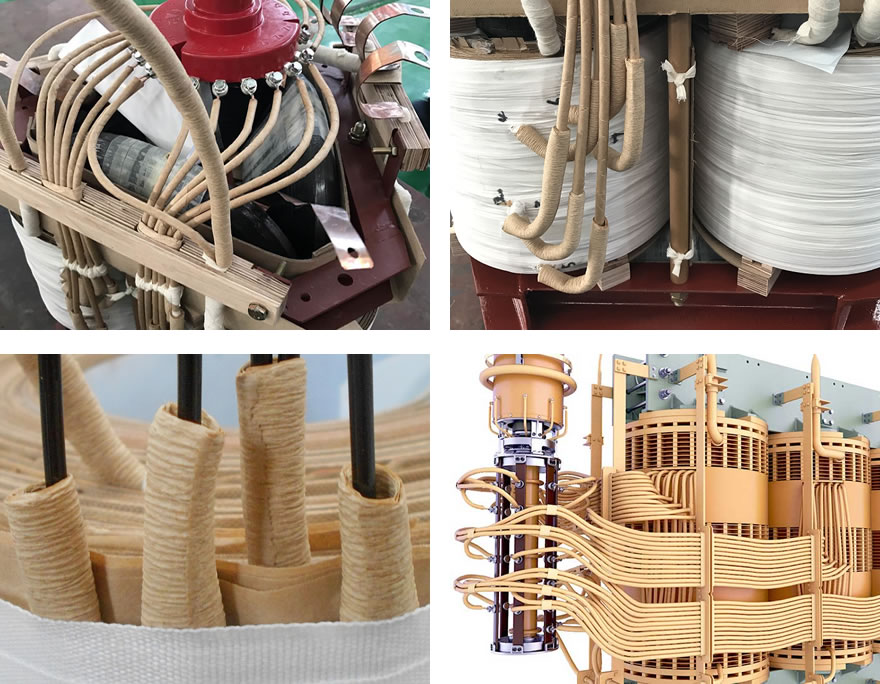

Introduction of Crepe Paper

Crepe paper is a flexible electrical insulation material widely used in oil-immersed transformers.

Made from high-purity electrical paper through mechanical stretching and creping, it features a unique wrinkled surface that offers excellent flexibility, oil absorption, and dielectric properties.

These characteristics make it an ideal choice for insulating and protecting conductors and windings in transformer applications.

What Is Crepe Paper for Electrical Insulation?

Electrical crepe paper is produced by impregnating pure cellulose electrical paper and forming a fine crepe pattern on its surface.

The resulting texture increases elongation and surface area, allowing the paper to conform tightly to irregular shapes such as winding conductors and corners.

It also enhances oil retention and ensures a stable oil–paper insulation system inside transformers.

Main Functions in Oil-Immersed Transformers

1. Conductor Wrapping

Crepe paper is wrapped around transformer winding conductors (especially rectangular or flat copper wires) to provide insulation between turns and prevent short circuits or partial discharges.

Its high stretchability ensures smooth wrapping even around sharp bends without tearing.

2. Interlayer and Turn-to-Turn Insulation

Placed between winding layers or turns, crepe paper enhances dielectric strength and prevents electrical breakdown.

It maintains insulation integrity under mechanical and thermal stress.

3. Oil Circulation and Heat Dissipation

The creped surface naturally forms fine oil channels that promote transformer oil circulation, improving heat dissipation and temperature stability during operation.

4. Oil Absorption and Dielectric Stability

Crepe paper absorbs transformer oil efficiently, forming a uniform oil–paper composite system.

This structure improves dielectric stability and extends insulation life, especially under long-term thermal and electrical stress.

5. Mechanical Cushioning and Stress Relief

At winding ends or lead exits, crepe paper acts as a mechanical buffer, reducing vibration and stress concentration.

It prevents insulation cracking and enhances the overall durability of the transformer.

Typical Applications

| Application Area | Function |

|---|---|

| Conductor wrapping | Electrical insulation and oil absorption |

| Layer and turn insulation | Prevents breakdown and partial discharge |

| Winding ends and leads | Mechanical cushioning and stress relief |

| Oil channels and spacers | Improves oil flow and heat dissipation |

Advantages of Crepe Paper in Transformer Insulation

Excellent flexibility and elongation, suitable for complex winding structures

Superior oil absorption, forming a stable insulation system with transformer oil

Reliable electrical insulation and high dielectric strength

Good heat and oil resistance, ensuring long-term stability

Cost-effective and easy to process, adaptable to different designs and dimensions

Conclusion

Crepe paper is one of the most essential insulation materials for oil-immersed transformers.

It provides effective electrical insulation, oil absorption, and mechanical protection for windings and conductors.

By enhancing both thermal management and dielectric reliability, crepe paper plays a key role in ensuring the safe, efficient, and long-lasting operation of transformers.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations