AMA Insulation Paper Composition and Selection Guide

1. Structure and Features of AMA Insulation Paper AMA insulation paper (Aromatic polyamide paper + Polyester film + ...

1. Structure and Features of AMA Insulation Paper

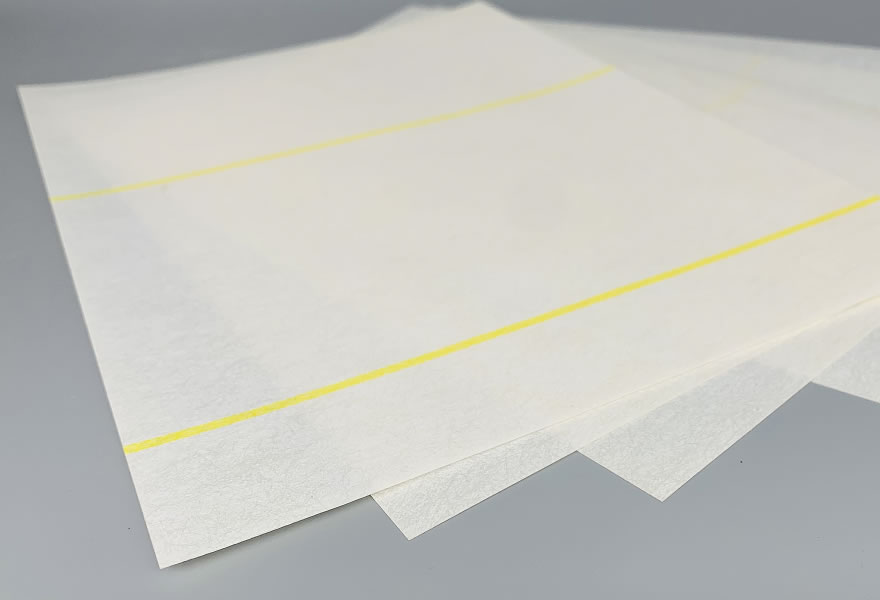

AMA insulation paper (Aromatic polyamide paper + Polyester film + Aromatic polyamide paper) is a three-layer composite insulation material commonly used in transformers, motors, and inductors.

Structure:

A (top layer): Aramid paper (Nomex)

M (middle layer): Polyester film (PET)

A (bottom layer): Aramid paper (Nomex)

Features:

Excellent thermal and electrical insulation from aramid paper

Good mechanical strength and toughness from polyester film

Typical thermal class: F (155 °C) or H (180 °C)

2. Common Models and Characteristics

| Model | Structure (mm) | Thermal Class | Features | Typical Application |

|---|---|---|---|---|

| AMA 0.15 | 0.05A + 0.05M + 0.05A | F/H | Flexible, easy to form | Slot insulation for small motors |

| AMA 0.20 | 0.05A + 0.10M + 0.05A | F/H | Balanced performance | General purpose |

| AMA 0.25 | 0.075A + 0.10M + 0.075A | H | Higher strength | Slot and interlayer insulation |

| AMA 0.30–0.40 | 0.10A + 0.15M + 0.10A | H | Strong compressive strength | Layer insulation in dry-type transformers |

| AMA 0.50+ | Custom | H | Very high strength | End or spacer insulation for large transformers |

3. Key Selection Principles

Based on Application Position

| Application | Recommended Model | Description |

|---|---|---|

| Motor slot insulation | AMA 0.15–0.20 | Requires flexibility and formability |

| Slot liner or end insulation | AMA 0.20–0.25 | Balance of mechanical and electrical properties |

| Dry-type transformer interlayer insulation | AMA 0.25–0.40 | High dielectric strength and durability |

| Transformer end or spacer insulation | AMA 0.40–0.50 | Strong mechanical and compressive strength |

Based on Operating Temperature

≤ 155 °C → Choose F-class AMA

≤ 180 °C → Choose H-class AMA

For long-term high temperature and high voltage → Choose H-class, thicker structure

Based on Voltage Level

| Voltage | Recommended Thickness |

|---|---|

| ≤ 1 kV | 0.15–0.20 mm |

| 1–10 kV | 0.25–0.40 mm |

| ≥ 10 kV | ≥ 0.40 mm or multi-layer laminated use |

Based on Mechanical Requirements

For high mechanical strength (e.g., end insulation, spacers) → use thicker AMA (0.30–0.50 mm)

For flexibility and forming (e.g., slot or corner insulation) → use thin AMA (0.15–0.20 mm)

4. Common Brands

DuPont NOMEX series (high-end international brand)

Baoke, Huawei, Southern Electrical Materials, Jinzhang Tech (cost-effective domestic brands in China)

Typical product labels: AMA-HA, AMA-F, Nomex-Film-Nomex composites

5. Summary of Selection Rules

If you’re unsure which model to choose, use this simple rule:

Application + Temperature Class + Required Thickness → AMA Model

Examples:

Small motor slot insulation (155 °C) → AMA 0.20 F-class

Dry-type transformer interlayer (180 °C) → AMA 0.30 H-class

High-voltage transformer end insulation (180 °C) → AMA 0.50 H-class

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations