How to Select Pressboard Based on Transformer Type Transformer Pressboard is an essential solid insulation material ...

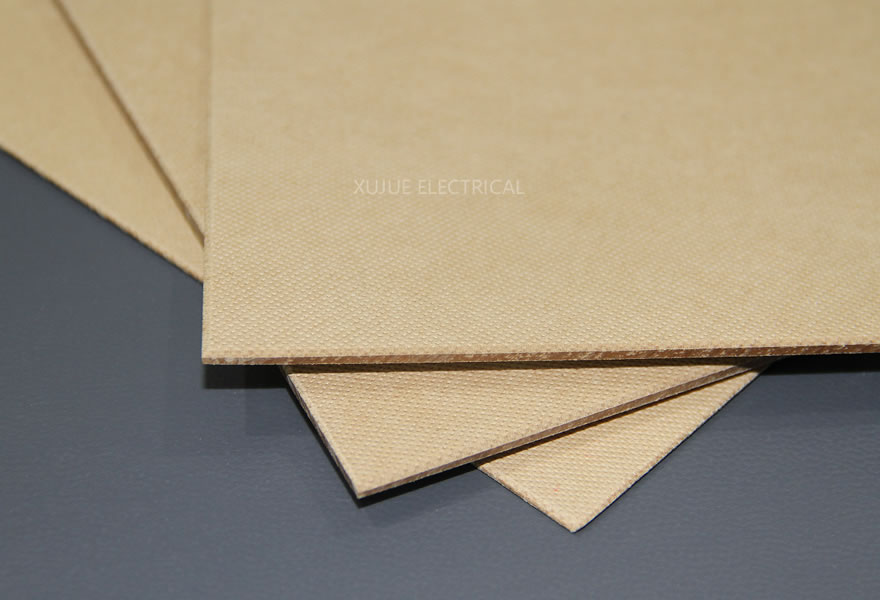

Transformer Pressboard is an essential solid insulation material in oil-immersed transformers. Different transformer types vary significantly in voltage level, short-circuit withstand capability, thermal requirements, and mechanical stress. Therefore, the selection of pressboard must be optimized according to the transformer’s structure and operating conditions.

This guide covers pressboard selection for distribution transformers, power transformers, special transformers, and dry-type transformers.

Lower voltage levels

Simpler structure

Cost-efficient and stable performance

Widely used in industrial, commercial, and municipal distribution networks

| Application | Suggested Specification |

|---|---|

| Interlayer & end insulation | 1–2 mm normal-density pressboard |

| Oil duct spacers & separators | 3–4 mm normal-density pressboard |

| Structural support components | 5–8 mm normal- or medium-density pressboard |

Electrical stress is relatively low; normal density is sufficient

A-class (105°C) insulation meets thermal requirements

Cost-effective for mass-production distribution transformers

High voltage levels

Requires strong short-circuit mechanical strength

Complex oil ducts and multi-layer insulation structures

Mainly applied in substations and heavy-industry projects

| Application | Suggested Specification |

|---|---|

| Interlayer/section insulation | 1–3 mm high-density pressboard |

| Coil end insulation | 3–5 mm high-density pressboard |

| Oil duct panels / spacers | 5–10 mm high-density pressboard |

| Press rings / structural components | ≥8 mm high-density pressboard |

High-density pressboard offers higher dielectric strength (≥60 kV/mm)

Superior mechanical stability under short-circuit forces

Minimal deformation after machining, suitable for precision oil duct design

Large currents and fluctuating loads

Strong electrical and mechanical impacts

High thermal variations

Harsh operating conditions

| Transformer Type | Recommended Pressboard |

|---|---|

| Rectifier / converter transformers | High-density, high-thermal-class pressboard (F-class 155°C) |

| Furnace transformers | High-density and thick pressboard (8–12 mm) for structural support |

| Traction / railway transformers | Vibration-resistant, high-temperature pressboard |

| PV and wind power transformers | Moisture-resistant high-density pressboard |

Requires excellent mechanical and thermal stability

Must withstand heavy short-circuit forces

Higher thermal class improves long-term reliability in unstable environments

Characteristics:

Air-cooled or forced-air-cooled

No insulating oil, full dependence on solid insulation

Frequent thermal shocks and localized hot spots

Recommended Pressboard Specifications:

1–3 mm boards: interlayer and section insulation

3–6 mm boards: structural supports and inner liners

F-class (155°C) or H-class (180°C) materials are preferred

Reasons:

Dry-type transformers experience higher temperature rises

High-density materials ensure dimensional stability in non-oil environments

| Transformer Type | Priority Material | Thickness | Density | Thermal Class |

|---|---|---|---|---|

| Distribution | Normal-density | 1–5 mm | Normal/Medium | A-class |

| Power | High-density | 1–10 mm | High density | A or F-class |

| Special | High-thermal, high-density | 3–12 mm | High density | F-class or above |

| Dry-type | High-thermal, high-density | 1–6 mm | Medium/High density | F/H-class |

Check short-circuit withstand capability (determines density)

Select thickness based on oil duct structure

Control moisture content ≤ 7% (pre-dry before assembly)

CNC or laser-cut parts are recommended for high-end transformers

For outdoor or high-humidity areas, choose moisture-resistant high-density board

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778