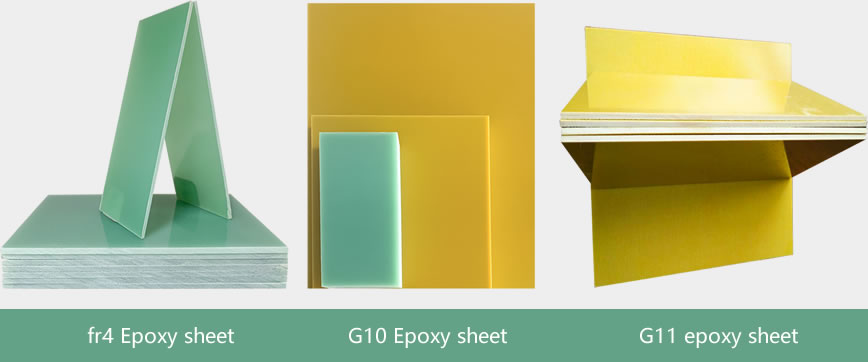

FR4 vs G10 vs G11 epoxy sheet: Density and Thermal Conductivity Comparison Density Comparison (FR4 vs G10 vs G11) A...

All three materials are glass fiber–reinforced epoxy laminates, so their densities are very similar:

| Material | Density (g/cm³) | Notes |

|---|---|---|

| FR4 | 1.85–2.0 (typical 1.9) | Contains flame-retardant additives; UL94 V-0 |

| G10 | 1.80–2.0 (typical 1.9) | No flame retardant; mechanically stable |

| G11 | 1.85–2.0 (typical 1.95) | Enhanced high-temperature performance; Class F (155°C) |

Summary: The densities are nearly identical, with G11 slightly higher on average.

All three materials are low thermal-conductivity insulation laminates:

| Material | Thermal Conductivity (W/m·K) | Notes |

|---|---|---|

| FR4 | 0.25–0.35 (typical 0.29) | Flame-retardant; low thermal conductivity |

| G10 | 0.25–0.30 | Similar to FR4, without flame retardant |

| G11 | 0.28–0.35 | More stable at high temperature; slightly higher thermal conduction |

Summary: G11 > FR4 ≥ G10 in thermal conductivity (differences are small).

| Performance | FR4 | G10 | G11 |

|---|---|---|---|

| Flame Retardancy | ★★★ (UL94 V-0) | ★ (Non-FR) | ★ (Non-FR) |

| Temperature Class | 130°C (Class B) | 130°C (Class B) | 155°C (Class F) |

| Mechanical Strength | Stable | Slightly higher than FR4 | Most stable at high temperature |

| Typical Applications | PCB, electrical insulation | Industrial structural parts, insulation | High-temp, high-insulation, high-frequency applications |

Density: Nearly the same for all three materials (1.85–2.0 g/cm³).

Thermal Conductivity: 0.25–0.35 W/m·K, with G11 slightly higher.

G11 offers the best high-temperature performance.

FR4 offers flame retardancy.

G10 is a general-purpose mechanical grade.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778