1. Material Composition & Manufacturing Process GPO-3 (Glass fiber reinforced unsaturated polyester sheet) Base...

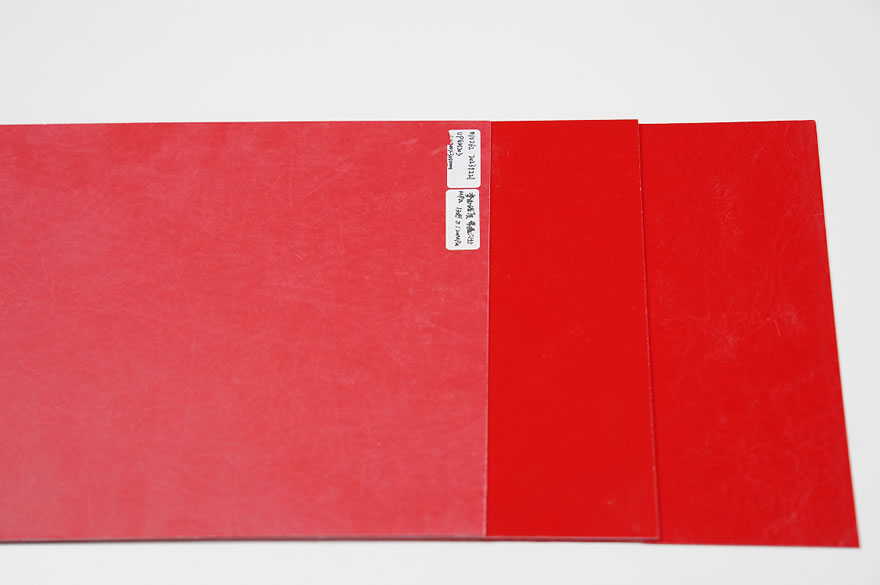

GPO-3 (Glass fiber reinforced unsaturated polyester sheet)

Base: Glass fiber reinforcement

Resin system: Unsaturated polyester resin

Process: Molded sheet, with smooth or matte surface options

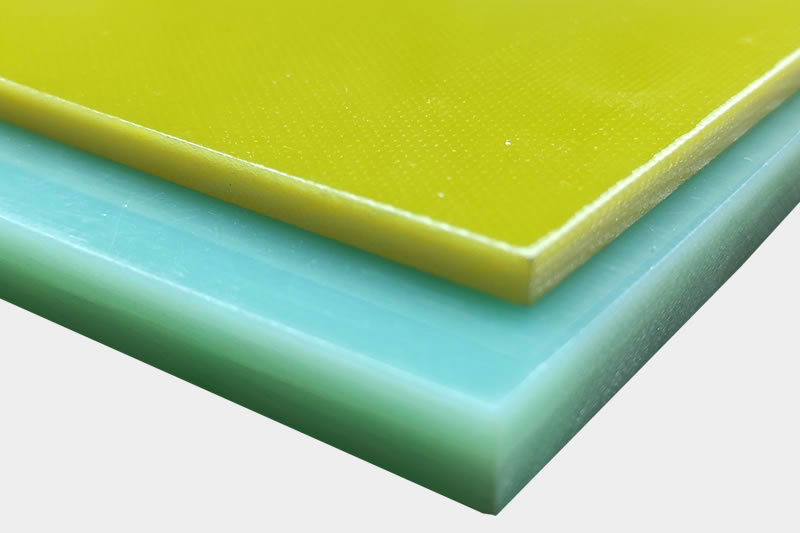

FR-4 (Glass cloth reinforced epoxy sheet, flame-retardant type)

Base: Glass cloth

Resin system: Epoxy resin with flame retardants

Process: Laminated sheet, mainly used for PCB

G10 sheet (Glass cloth reinforced epoxy sheet, non-flame-retardant type)

Base: Glass cloth

Resin system: Epoxy resin (without flame retardants)

Process: Laminated sheet, similar to FR-4 but without flame retardancy

| Property | GPO-3 | FR-4 | G10 |

|---|---|---|---|

| Thermal class | Class B (130℃) / Class F (155℃) | Class B (130℃) ~ Class H (180℃) | Class B (130℃) |

| Flame resistance | Excellent (UL94 V-0) | Excellent (UL94 V-0) | Non-flame-retardant (HB) |

| Electrical performance | Good, excellent arc resistance and tracking resistance | Excellent dielectric performance, suitable for high-frequency, high-speed signals | Good, but less stable than FR-4 at high frequency |

| Mechanical strength | High, especially impact resistance | High strength, excellent dimensional stability | High strength, slightly lower than FR-4 |

| Moisture resistance | Excellent | Good, but performance may decline in long-term humid environments | Fair |

| Machinability | Easy to machine, cost-effective | Machinable, but mainly used in PCB etching and drilling | Machinable |

| Cost | Relatively low | Medium to high | Medium |

GPO-3

Transformers, switchgear, motor insulation partitions

Insulation supports, busbar supports, phase barriers in electrical equipment

Suitable for insulation and structural parts in medium- and low-voltage power systems

FR-4

Standard material for printed circuit boards (PCBs)

High-frequency, high-speed circuits, precision electronics

Also used in battery insulation sheets, electronic insulation spacers

G10

Mechanical structural parts, non-flame-retardant insulation parts

Military, aerospace components, knife handles, sports equipment

Suitable for high-strength applications without strict flame-retardant requirements

Flame-retardant requirements

With flame-retardant requirement: choose FR-4 or GPO-3

Without flame-retardant requirement: G10 is cost-effective

Application field

Electrical insulation (transformers, switchgear): choose GPO-3

PCB, circuit substrate: choose FR-4

Mechanical structural parts, tool components: G10 is suitable

Operating environment

Humid/arc environment: GPO-3 performs better

High-frequency electronic signals: FR-4 is preferred

General insulation + strength: G10 is sufficient

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778