Garolite G10 FR4 Introduction and Performance Comparison

Garolite G-10 FR4: Product Introduction, Performance Comparison, and Applications 1. Product Introduction Ga...

Garolite G-10 FR4: Product Introduction, Performance Comparison, and Applications

1. Product Introduction

Garolite G-10

G-10 epoxy sheet is a composite material laminated under high temperature and pressure using glass fiber cloth impregnated with epoxy resin. It belongs to the G-series under the NEMA (National Electrical Manufacturers Association) standard and contains no flame-retardant additives, relying instead on the inherent properties of epoxy resin.

Base Material: Glass fiber cloth + halogen-free epoxy resin.

Color: Typically natural beige or customizable.

Key Advantages: High mechanical strength, excellent insulation, chemical resistance, and thermal stability.

FR4 is a general term for glass-reinforced epoxy laminates, classified under the NEMA flame-retardant grade and compliant with the UL94 V-0 standard (self-extinguishing).

Base Material: Glass fiber cloth + flame-retardant epoxy resin (containing bromine or other additives).

Color: Commonly green (for PCBs) or industrial colors.

Key Advantages: Superior flame resistance, strong electrical properties, and widespread use in electronics.

2. Performance Comparison

| Property | Garolite G-10 | FR4 |

|---|---|---|

| Flame Resistance | Non-flame-retardant (UL94 HB) | UL94 V-0 (self-extinguishing) |

| Mechanical Strength | Higher (flexural: 500-600 MPa) | Moderate (flexural: 400-500 MPa) |

| Thermal Resistance | Continuous use ≤130°C | Continuous use ≤120-130°C |

| Dielectric Constant (1MHz) | ~4.5-5.0 | ~4.3-4.9 |

| Water Absorption | ≤0.10% | ≤0.15% |

| Chemical Resistance | Excellent (acid/alkali/solvent) | Good (reduced by flame retardants) |

| Eco-Friendliness | Halogen-free (RoHS-compliant) | Contains bromine (RoHS-restricted variants exist) |

| Typical Thickness | 0.1mm – 50mm | 0.2mm – 3.2mm (PCB standard) |

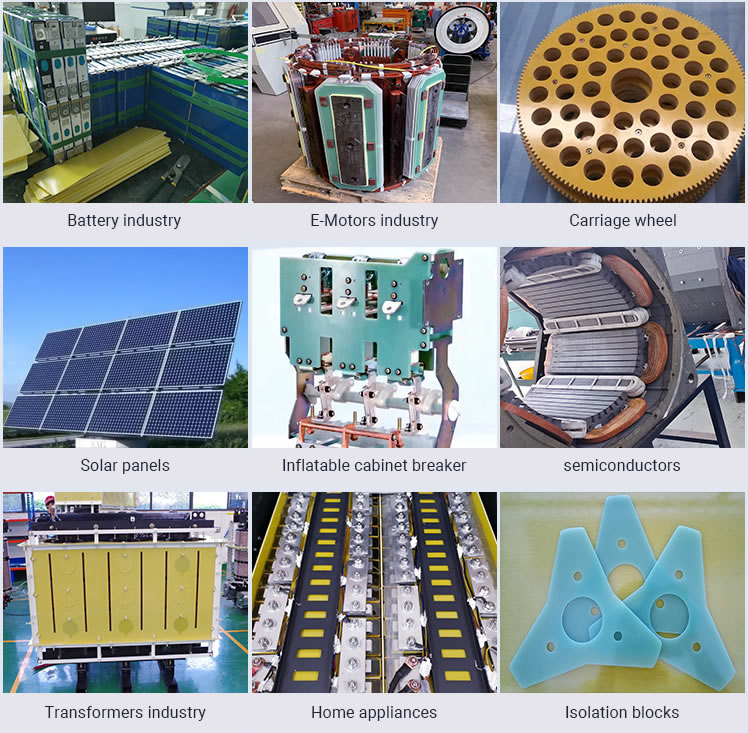

3. Application Fields

Garolite G-10

Mechanical: Insulating spacers, bearings, gear bushings (high-load, wear-resistant).

Electrical: Transformer insulation, high-voltage switch components (arc resistance >150 sec).

Harsh Environments: Chemical equipment linings, vacuum systems (low outgassing).

Aerospace: Satellite components, radiation-resistant parts.

FR4 sheet

Electronics: PCB substrates (90% of global PCBs use FR4).

Flame-Retardant Devices: Power supply housings, motor insulation (UL-certified).

Consumer Electronics: Smartphone/computer motherboards, LED panels.

Automotive: ECU modules, sensor substrates.

4. Selection Guidelines

Choose G-10 :

High mechanical strength or chemical resistance is critical (e.g., chemical processing).

Flame retardancy is unnecessary, but RoHS compliance is required.

Operating in high-temperature environments (e.g., motor insulation).

Choose FR4 :

Flame resistance is mandatory (e.g., consumer electronics, public infrastructure).

High-frequency circuit design is needed (low-loss variants available).

Cost efficiency and mass production are priorities (mature PCB supply chain).

5. Additional Notes

Eco-Friendly Trends: Some FR4 now uses halogen-free flame retardants (e.g., phosphorus-based) for RoHS 2.0 compliance.

Processing Differences: G-10 generates glass fiber dust during drilling (requires PPE), while FR4 cutting may release brominated compounds.

Advanced Alternatives: For extreme conditions, consider G-11 (180°C thermal resistance) or high-frequency FR4 variants (e.g., Rogers 4350B).

By comparing these materials, users can select the optimal choice based on specific requirements (flame retardancy, strength, environmental resistance).

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL