G11 Epoxy Sheet Application in Small Wind Turbine Generators

Application of G11 Epoxy Sheet in Small Wind Turbine Generators Small wind turbine generators are widely used in dis...

Application of G11 Epoxy Sheet in Small Wind Turbine Generators

Small wind turbine generators are widely used in distributed energy systems, rural electrification, telecom power supply, and hybrid renewable energy projects. In these systems, electrical insulation materials must withstand high temperature, mechanical stress, vibration, and long-term outdoor operation.

G11 epoxy sheet, a high-performance epoxy glass fiber laminate, has become a preferred insulation solution for small wind turbine generators.

What Is G11 Epoxy Sheet?

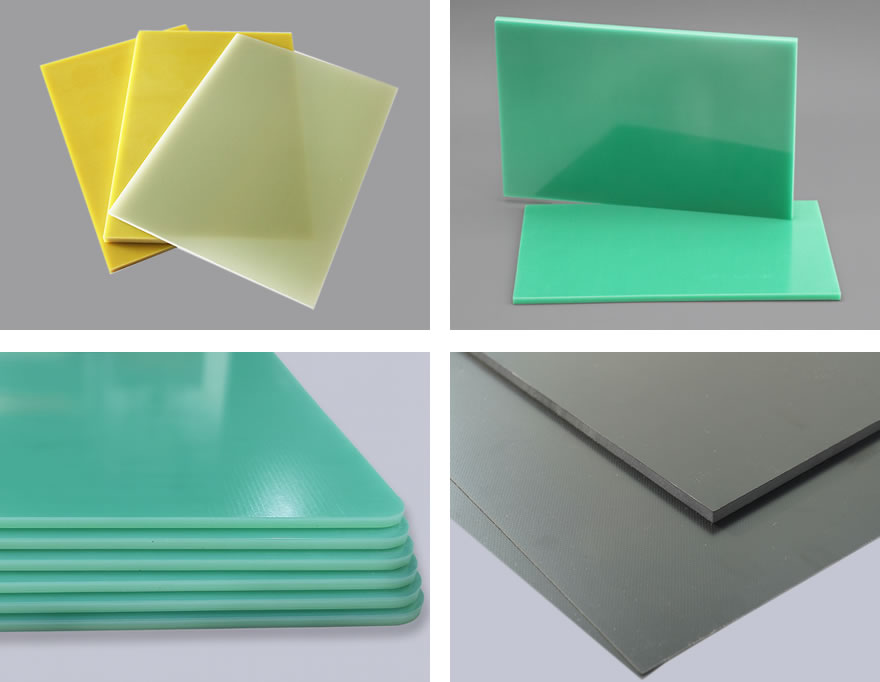

G11 epoxy sheet is manufactured from woven fiberglass cloth impregnated with epoxy resin and cured under high temperature and pressure. It is designed for high thermal class (Class H, 180°C) electrical insulation applications.

Key Properties:

Thermal class: H (180°C)

High dielectric strength

Excellent mechanical strength

Low moisture absorption

Good dimensional stability

Strong resistance to vibration and fatigue

Why G11 Epoxy Sheet Is Suitable for Wind Turbine Generators

Small wind turbines operate in harsh environments: wind vibration, temperature fluctuation, humidity, salt mist, and continuous electrical load. G11 epoxy sheet meets these challenges due to:

| Requirement | G11 Performance |

|---|---|

| Heat resistance | Stable at high operating temperatures |

| Electrical insulation | High breakdown voltage |

| Mechanical strength | Supports structural loads |

| Moisture resistance | Maintains insulation in humid climate |

| Vibration resistance | Excellent fatigue performance |

Main Applications in Small Wind Turbine Generators

Generator Stator Slot Insulation

G11 sheets are machined into slot liners and phase insulation parts, ensuring electrical isolation between windings and the stator core.

End Winding Support Components

Used as end winding support rings, spacers, and fixing plates to improve mechanical stability during high-speed rotation.

Terminal Boards and Insulating Plates

G11 epoxy sheet is widely applied in generator terminal boxes, control cabinets, and junction boards.

Rotor Insulation Parts

Provides insulation separation between conductive components in rotor assemblies.

Structural Insulation Brackets

Used for mounting electronic modules, sensors, and rectifier units inside the nacelle.

Advantages Over Other Insulation Materials

Compared with G10, phenolic laminates, or polyester boards:

Higher temperature resistance than G10

Better mechanical strength than phenolic boards

Longer service life in outdoor environments

Lower maintenance requirement

Better long-term electrical stability

Typical Specifications for Wind Turbine Use

| Item | Value |

|---|---|

| Thickness | 0.5 mm – 50 mm |

| Color | Yellow / Light green |

| Density | 1.8 – 2.0 g/cm³ |

| Dielectric strength | ≥ 35 kV/mm |

| Operating temperature | Up to 180°C |

Application Benefits for Wind Power Systems

Using G11 epoxy sheet in small wind turbine generators helps:

Improve generator reliability

Reduce insulation aging risk

Enhance vibration resistance

Extend service life

Lower maintenance costs

Ensure stable power output

Conclusion

G11 epoxy sheet is an ideal insulation material for small wind turbine generators due to its excellent electrical, thermal, and mechanical properties. From stator insulation to structural support components, it plays a critical role in ensuring safe, stable, and long-term operation of wind power equipment.

For manufacturers of small wind turbines, selecting G11 epoxy sheet is a cost-effective and technically reliable solution for high-performance generator insulation systems.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-06 2026Types and Selection of Transformer Laminated Wood

- 03-05 2026Insulation Raw Materials — Epoxy Resin Price Increase

- 03-05 2026NMN Flexible Insulation Material for Motor Winding

- 03-04 2026G11 Epoxy Glass Laminate for Generator Insulation

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth