Epoxy Boards: Multi-Dimensional Safety Guardians in Lithium Battery Packs With the rapid development of the new ener...

With the rapid development of the new energy vehicle and energy storage industries, the safety, energy density, and service life of lithium battery packs have become core technical challenges.

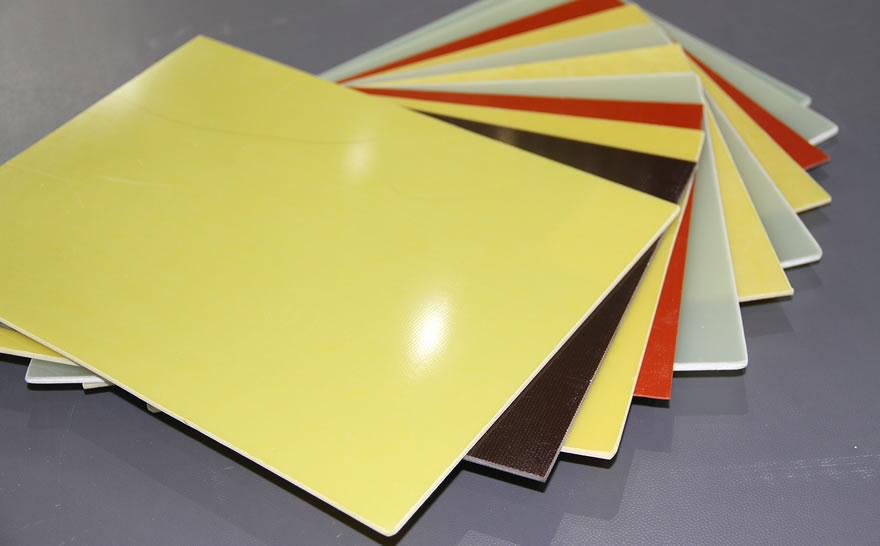

Thanks to their unique material properties, epoxy resin boards (ERB) have evolved from passive protective components into multi-functional materials integrating insulation, flame retardancy, structural support, and thermal management. They are now indispensable within modern battery packs.

Quick Selection Guide for Lithium Battery Projects

General lithium battery modules / PACK systems

FR4 insulation epoxy sheet (recommended choice)

High mechanical strength with no flame-retardant requirement

G10 insulation epoxy sheet

High-power, high-temperature, or energy storage applications (ESS)

G11 insulation epoxy sheet

This article analyzes epoxy boards from three perspectives: performance advantages, core functions, and innovative applications.

Epoxy boards feature a volume resistivity exceeding 10¹⁵ Ω·cm, effectively blocking abnormal current conduction between battery electrodes or within modules.

In battery packs, epoxy boards are commonly used as insulating spacers between cells or as protective covers behind BMS boards, preventing short circuits caused by metallic debris or accidental contact.

Under high temperatures, epoxy boards form a carbonized protective layer that isolates oxygen and slows flame propagation. Experimental studies show that:

Battery modules equipped with 2 mm epoxy boards extend thermal runaway propagation time to 2.3 times that of modules without separators;

4 mm epoxy boards can effectively block chain thermal runaway reactions in series-connected modules.

These characteristics significantly enhance battery safety margins under extreme conditions such as nail penetration and overcharging.

Epoxy boards exhibit flexural strength exceeding 300 MPa, enabling them to absorb vibration and impact during vehicle operation.

In PACK modules, epoxy boards are often used as top protective layers, bolted to the enclosure to prevent deformation of cells caused by external compression or drops. Meanwhile, their low water absorption (<0.1%) ensures dimensional stability in humid environments.

In scenarios involving electrolyte leakage, epoxy boards demonstrate excellent resistance to strong acids and organic solvents, preventing swelling or material degradation.

In energy storage cabinets, epoxy board enclosures can withstand salt spray, humidity, and harsh climatic conditions, ensuring long-term reliability.

With a density of only 1.7–1.9 g/cm³, epoxy boards reduce weight by over 60% compared to metal protective components, contributing directly to higher battery energy density.

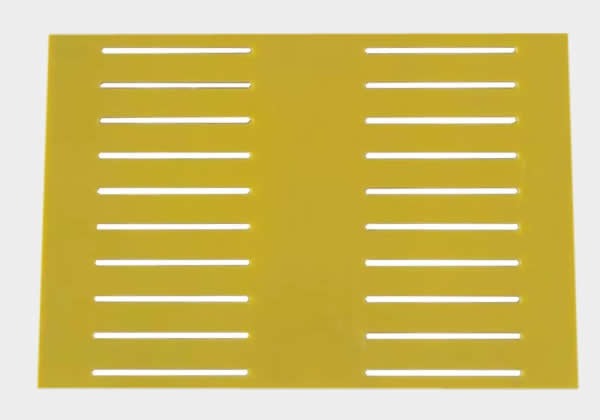

Their excellent machinability allows for customized cutouts, enabling precise layouts for sensing boards, wiring, and cooling air channels.

Due to their low thermal conductivity (≈0.2 W/m·K), epoxy boards effectively delay heat transfer. Experimental data shows that:

A 4 mm epoxy board can reduce the peak temperature of parallel modules by up to 137°C;

Thermal propagation time can be extended to 5.6 times that of packs without separators.

This delay provides a critical time window for BMS protection strategies to activate.

Cell Fixation: When combined with adhesive PP plates, epoxy boards form a stable structure featuring double-sided cell bonding and rigid top protection.

Electrical Integration: In racing battery packs, epoxy boards directly support busbar welding and embedded sensing board installation, reducing wiring length by more than 30%.

Vibration Damping: Used together with silicone pads and foam materials, epoxy boards help distribute mechanical stress and improve durability.

Thanks to their anti-aging performance and service life exceeding 10 years, epoxy boards significantly reduce PACK maintenance frequency.

In energy storage systems, epoxy board enclosures prevent corrosion-related sealing failures common in metal housings, thereby lowering total lifecycle replacement costs.

Smart Top Protective Layers: Next-generation PACK designs embed temperature sensors directly into epoxy board perforations, enabling real-time thermal runaway monitoring.

Lightweight Module Frames: Epoxy boards reinforced with carbon fiber composites offer enhanced specific strength and are being tested for flying vehicle battery systems.

Thermal-Conductive Insulating Integration: Modified epoxy boards filled with boron nitride (laboratory data) achieve thermal conductivity of up to 5 W/m·K while maintaining electrical insulation, addressing heat dissipation challenges in high-rate cells.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778