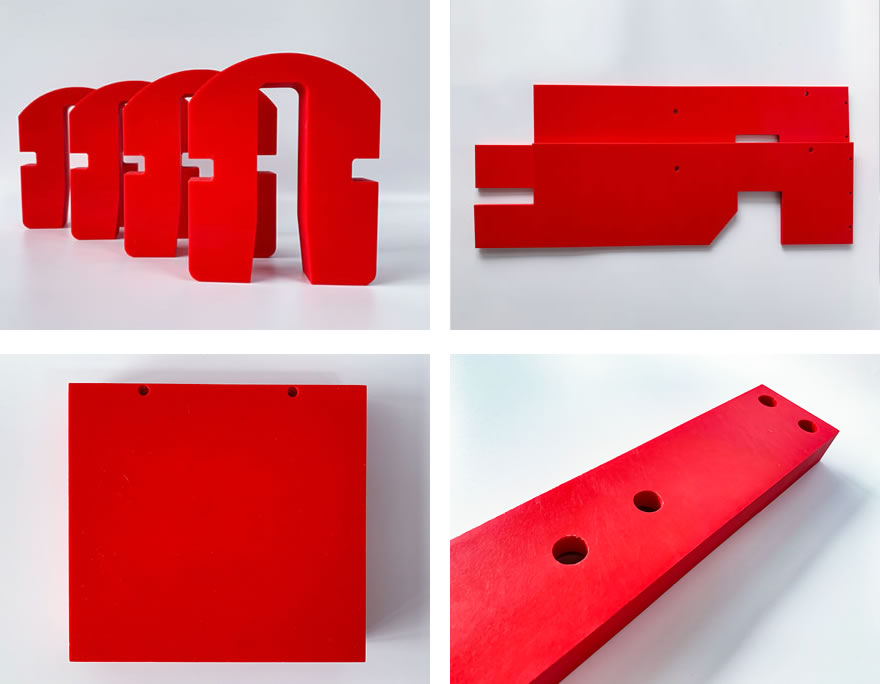

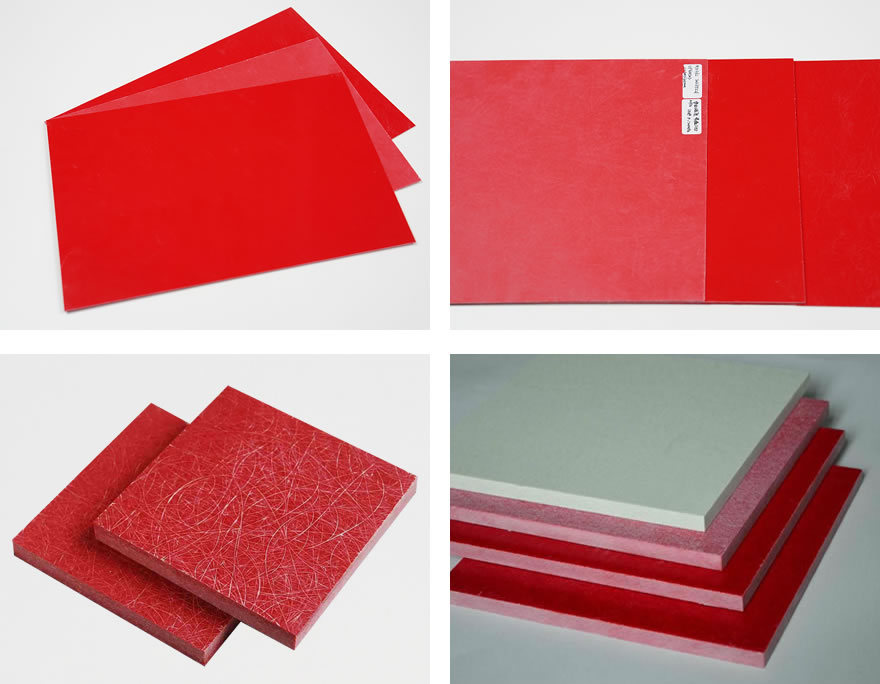

GPO-3 Insulating Laminate in Electrical Insulation Applications

GPO-3 insulating laminate is a cornerstone material in electrical insulation, leveraging its exceptional electrical p...

GPO-3 insulating laminate is a cornerstone material in electrical insulation, leveraging its exceptional electrical properties, flame retardancy, mechanical strength, thermal resistance, and dimensional stability. It is indispensable in medium/high-voltage electrical equipment. Key application scenarios and technical advantages are detailed below:

I. Core Application Scenarios

1. Dry-Type Transformers (Especially Epoxy-Resin Cast – SCB Type)

-

Insulating Frames/Spacers: Supports windings against electromagnetic forces and thermal stress; requires high mechanical strength and low shrinkage.

-

End Insulation/Interlayer Insulation: Isolates HV/LV windings to prevent creepage/flashover; relies on high dielectric strength (>10 kV/mm).

-

Blocks/Clamping Insulation: Secures windings and maintains cooling paths; demands thermal resistance (155°C class) and anti-creep properties.

-

Lead Supports: Secures and insulates leads against vibration-induced short circuits.

2. Medium/Low-Voltage Switchgear (e.g., KYN28, MNS, GCK)

-

Functional Barriers (Phase/Compartment Barriers):

→ Critical Role: Physically isolates phase busbars or functional units (e.g., circuit breaker/cable compartments) to block arc propagation.

→ Key Metric: CTI ≥ 600V (high comparative tracking index) ensures no conductive paths form in polluted/humid environments. -

Busbar Insulating Supports (Clamps/Brackets):

→ Secures Cu/Al busbars to maintain phase-to-phase/ground clearances (e.g., ≥125mm for 10kV systems).

→ Withstands short-circuit electrodynamic forces (flexural strength >200 MPa). -

Contactors/Arc Chute Insulation:

→ Encloses breaker contacts for insulation and arc control; requires arc resistance (>180s). -

Operating Plates/Shutters: Insulating substrates for mechanical interlock components.

3. Motors & Generators (HV/Special Motors)

-

Slot Wedges/Slot Insulation: Secures windings and isolates cores; resists corona degradation (critical for VFD motors).

-

End-Winding Phase Insulation: Prevents phase-to-phase shorts; requires flexibility for binding processes.

-

Insulating End Shields/Ventilation Barriers: Isolates windings from housings; withstands thermal rise (155°C H-class continuous).

4. Busway Systems

-

Phase-Separation Blocks: Isolates densely packed phase conductors; key metrics include dielectric strength and flame retardancy (UL94 V-0).

-

Joint Insulating Covers: Protects busbar connections against foreign objects and electric shock.

5. Electrical Devices & Components

-

Relay/Contactor Bases: Insulating support for live parts; dimensional stability ensures contact alignment.

-

Terminal Blocks/Junction Plates: Isolates multiple conductors; high CTI prevents tracking.

-

Insulating Operating Rods/Handles: Live-part isolation for manual switching devices.

II. Unmatched Technical Advantages

| Property | Specification/Feature | Critical Problem Solved |

|---|---|---|

| Electrical Insulation | Dielectric Strength ≥12 kV/mm Volume Resistivity >10¹³ Ω·cm |

Prevents HV breakdown; ensures safe clearances |

| Flame Retardancy | UL94 V-0 (self-extinguishing <10s) Glow-Wire Ignition ≥960°C |

Suppresses arc-induced fires; meets IEC 60695 |

| Tracking Resistance | CTI ≥ 600V (up to PLC 0 class) | Avoids surface carbonization in polluted/humid conditions |

| Mechanical Strength | Flexural Strength 200-300 MPa Tensile Modulus >10 GPa |

Supports heavy busbars/windings; resists short-circuit forces |

| Thermal Resistance | Continuous Use 155°C (H-class) Short-Term >180°C |

Withstands transformer/motor thermal rise; delays aging |

| Dimensional Stability | Low CTE (≤3×10⁻⁵/K) Water Absorption <0.1% |

Ensures precision assembly; no deformation in humidity |

| Arc Resistance | ASTM D495 >180 seconds | Endures switching arc erosion |

III. Selection & Design Guidelines

-

Thickness vs. Voltage Rating:

→ LV (400V): 1.5-3mm

→ MV (10kV): 4-8mm

→ HV (35kV+): Custom laminated structures required. -

CTI Class Selection:

→ For Pollution Degree 3/4 (e.g., industrial sites), CTI≥600V is mandatory (e.g., GPO-3™). -

Processing Compatibility:

→ CNC Machining: Complex parts (e.g., contactors)

→ Punching: Mass production of standard plates/spacers

→ Lamination: Ultra-thick components (>30mm) require multi-stage hot pressing. -

Certification Requirements:

→ International: UL (E331910), IEC 60455

→ China: GB/T 5132.1 (Industrial rigid laminated sheets based on thermosetting resins for electrical purposes)

IV. Advantages Over Alternative Materials

| Material | Disadvantages vs. GPO-3 | GPO-3 Superior Applications |

|---|---|---|

| Epoxy Laminate | Brittle; low impact resistance; CTI typically ≤250V | High CTI/arc-resistant environments (e.g., barriers) |

| SMC/BMC | Lower mechanical strength; poor fiber orientation | Load-bearing structures (e.g., busbar supports) |

| PPO | Difficult to achieve V-0; HDT <110°C | High-temperature scenarios (e.g., transformer ends) |

| Silicone | Extremely costly; insufficient strength | Cost-effective integrated insulation solution |

V. Typical Failure Modes & Prevention

Failure Modes:

Surface tracking (low CTI), delamination at high temperatures (resin degradation), fracture under short-circuit forces (low strength).

Preventive Measures:

Use high-CTI grade (≥600V) materials in humid environments.

Design thermal expansion gaps.

Perform dynamic stability simulation (e.g., ANSYS) for busbar supports.

Conclusion

GPO-3’s core value in electrical insulation lies in its integrated trifecta of properties:

High-voltage reliability (dielectric strength + CTI)

Active safety protection (V-0 flame retardancy + arc resistance)

Structural functionality (mechanical strength + dimensional stability)

This establishes GPO-3 as the premier material for insulating structures in equipment up to 35kV, especially in dry-type transformers, MV switchgear, and motor insulation where it remains irreplaceable. Prioritize CTI class, thickness design, and operating temperature during selection.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted