Electrical Insulating Pressboard Key Characteristics

Electrical insulating pressboard is a specialized insulating material designed for electrical equipment, primarily ma...

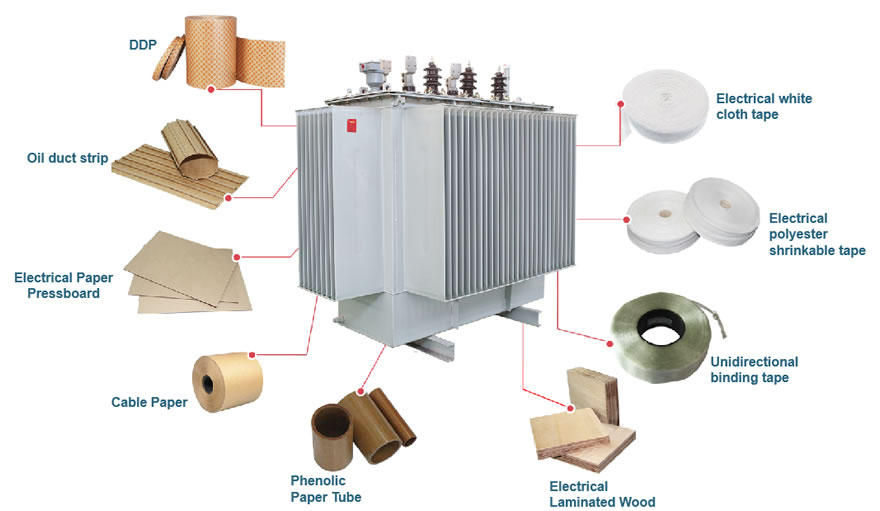

Electrical insulating pressboard is a specialized insulating material designed for electrical equipment, primarily manufactured from unbleached sulfate wood pulp through specialized processes. Utilizing wet-forming, high-temperature and high-pressure pressing, and drying treatments, it forms a dense and uniform fiber structure. Its core function is to isolate live components, preventing current leakage or short circuits. Widely used in transformers, motors, switchgear, and other high-voltage electrical devices, it serves as an indispensable foundational material in power systems.

1. Key Characteristics

High Dielectric Strength

Dielectric strength ranges from 12–20 kV/mm (1mm thickness), effectively blocking current and preventing breakdown.

Thermal Resistance

Long-term operational temperatures reach 105–155°C (temperature resistance classes: E to F), maintaining stable performance under high heat.

Superior Mechanical Properties

Longitudinal tensile strength ≥ 80 MPa, transverse ≥ 40 MPa; resistant to puncture and deformation, suitable for complex mechanical stress environments.

Low Moisture Absorption

Moisture content controlled at 5–8%, with moisture-proof treatments ensuring minimal performance degradation in humid conditions.

Chemical Stability

Resistant to oil, acids, alkalis, and compatible with transformer oil, ideal for oil-immersed equipment.

Eco-Friendliness & Safety

Halogen-free, flame-retardant (some models comply with UL94 V-0), RoHS-compliant, recyclable, and biodegradable.

2. Technical Parameters

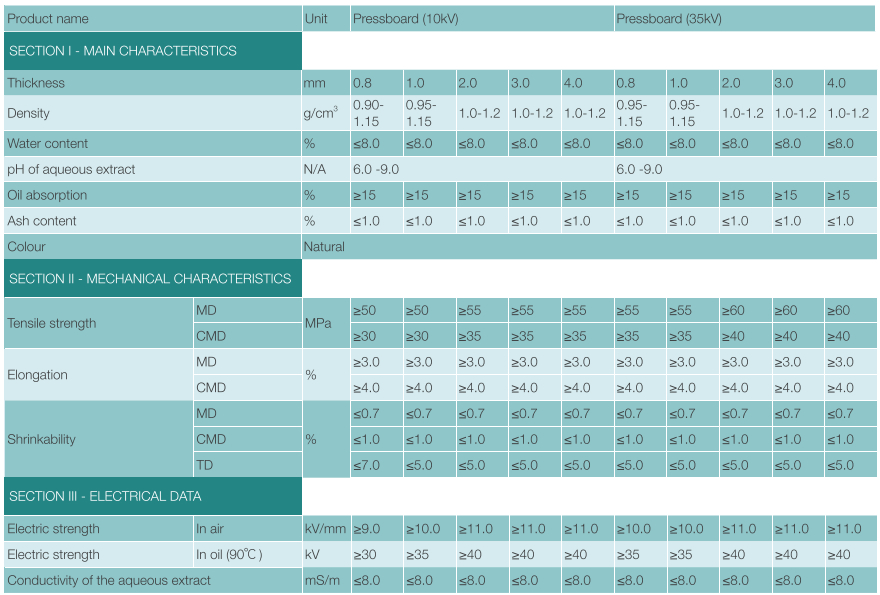

Pressboard data sheet for 10kv/35kv

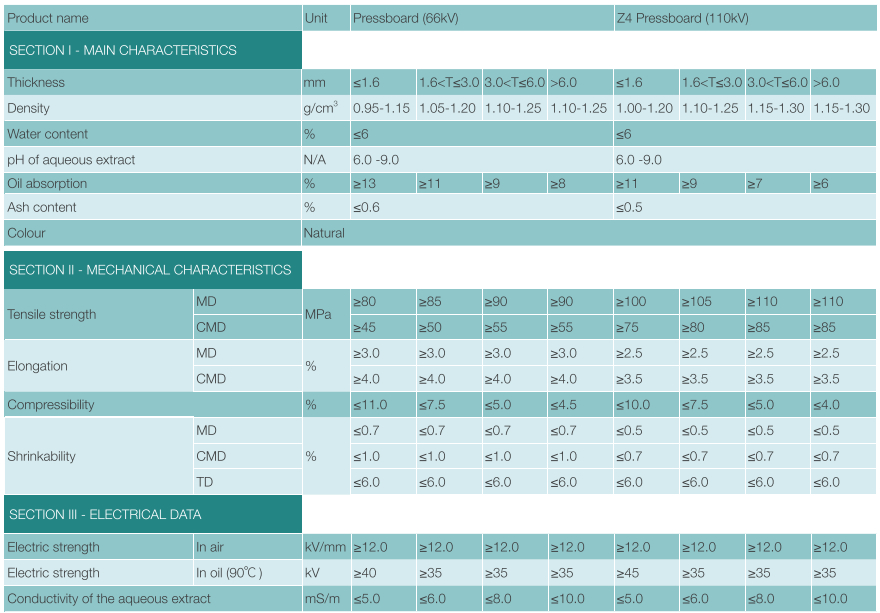

Pressboard data sheet for 66kv/110kv

3. Electrical Pressboard Applications

Transformers

Winding Insulation: Wraps coils to isolate high and low voltage windings.

Interlayer/End Insulation: Spacers and barriers prevent interturn short circuits.

Oil Gap Support: Secures winding positions in oil-immersed transformers.

Motors & Generators

Slot Insulation: Insulates conductors from iron cores in stator/rotor slots.

Phase Insulation Plates: Prevents contact between conductors of different phases.

High-Voltage Switchgear

Circuit breaker insulation barriers, busbar supports to enhance creepage distances.

Capacitors & Cables

Dielectric medium for capacitor core winding, insulation wrapping for cable joints.

Renewable Energy Systems

Internal insulation components in wind turbine converters and PV inverters.

4. Selection Guidelines

Voltage Level: Choose dielectric strength based on operational voltage.

Environmental Conditions: Opt for moisture-proof coatings in humid environments; prioritize Class F for high-temperature applications.

Processing Requirements: Pre-impregnated boards allow direct lamination, while non-impregnated types require post-treatment oil immersion.

Electrical insulating pressboard, with its balanced electrical and mechanical properties, is a cornerstone of power equipment safety. Selection should align with operational demands, technical parameters, and industry standards (e.g., IEC, ASTM) to ensure long-term reliability and compliance.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations