When selecting a phenolic cotton rod (also known as cotton phenolic laminate rod), it’s important to consider the mec...

When selecting a phenolic cotton rod (also known as cotton phenolic laminate rod), it’s important to consider the mechanical strength, electrical insulation, heat resistance, machinability, and environmental adaptability based on your specific application. The following is a practical selection guide to help you make an informed decision.

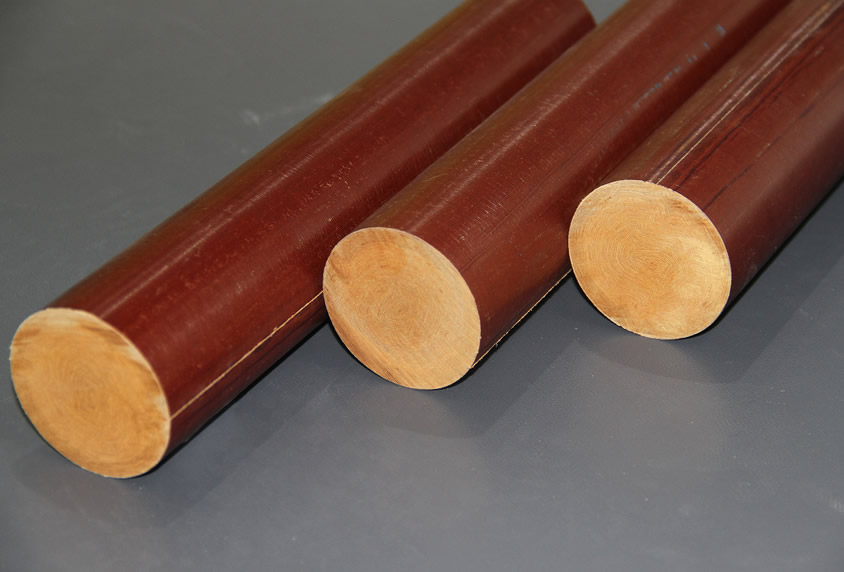

Phenolic cotton rods are made by impregnating cotton fabric with phenolic resin, then hot-pressing and machining into rod form. They offer the following advantages:

Excellent mechanical strength (especially impact resistance)

Good electrical insulation

Outstanding machinability (can be turned, milled, or threaded)

Dimensional stability, warp-resistant

Resistant to oil and wear

Clarify your needs based on the intended use:

| Application Type | Key Focus |

| Electrical equipment (e.g., motors, transformers) | Insulation, heat resistance, dimensional stability |

| Mechanical components (e.g., shafts, support rods) | Bending strength, impact toughness, wear resistance |

| Machined parts (e.g., bolts, positioning pins) | Machinability, strength, delamination resistance |

| Humid or oily environments | Oil and water resistance, shape retention |

| Property | Description |

| Mechanical Strength | Compressive strength > 300 MPa; Flexural strength > 120 MPa |

| Electrical Insulation | Volume resistivity ≥ 10⁹ Ω·cm; Dielectric strength ≥ 10 kV |

| Thermal Resistance | Class A to B; Working temperature -40°C to +120°C |

| Machinability | Easy to turn/thread; low risk of delamination |

| Water Absorption | ≤ 1.5%, suitable for moderately humid environments |

Common specifications:

Diameter: Usually from Φ6 mm to Φ100 mm (customizable)

Length: Standard 1000 mm (can be cut to length)

Example Recommendations:

| Use Case | Suggested Size | Reason |

| Insulating links | Φ12–Φ25 mm | Good insulation, sufficient strength, easy to machine |

| Mechanical shafts | Φ30–Φ60 mm | High strength, impact-resistant |

| Jigs & fixture columns | Φ50–Φ100 mm | High stability, precise machining |

| Precision parts | Φ10–Φ20 mm (high density) | Clean machining, high accuracy |

Avoid prolonged overheating: Continuous use above 120°C may soften the material or degrade performance.

Store in a dry environment: Protect from humidity, high temperatures, and direct sunlight.

Inspect for uniform core before machining: Avoid internal voids or impurities that affect strength.

Request material certifications: Such as COA, UL, RoHS, or third-party inspection reports.

Confirm the application scenario (electrical or mechanical)

List the key performance requirements

Choose the right size (diameter & length)

Check machinability and environmental resistance

Compare suppliers and verify material data

If you can provide specific working conditions (such as voltage level, temperature, mechanical load, etc.), we can help you match suitable models.

Contact us for product specifications and quotation sheet

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778