The role of crepe paper tube in oil-immersed transformer

In oil-immersed transformer, Crepe paper tube is one of the core insulation materials, which works together with insu...

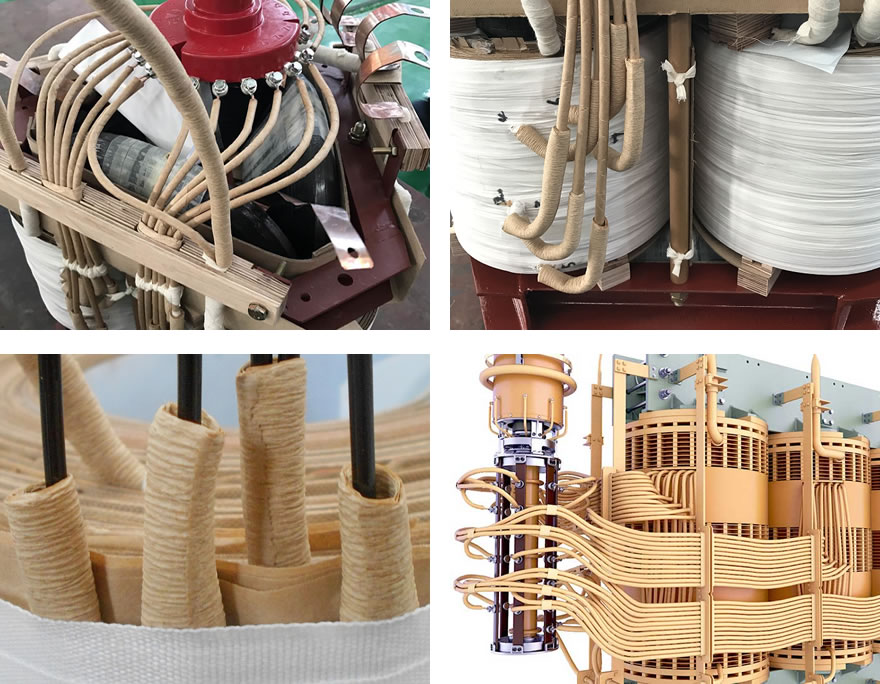

In oil-immersed transformer, Crepe paper tube is one of the core insulation materials, which works together with insulating oil to form an efficient and reliable insulation system. Its unique structure (surface wrinkles) and material properties make it excellent in high-voltage insulation, mechanical support and heat dissipation. The following is a detailed description:

The role of crepe paper tube in oil-immersed transformer

Main insulation barrier

High and low voltage winding isolation: wrapped in winding wires or layers to prevent electrical breakdown between high and low voltage windings.

Oil gap filling: The crepe structure of the crepe paper tube can absorb insulating oil, fill the tiny gaps between windings, evenly distribute the electric field, and avoid partial discharge.

Mechanical support and fixation

Coil skeleton: as a winding support skeleton, it maintains the roundness and stability of the coil and resists electromagnetic vibration and short-circuit impact.

Pads and partitions: used at the ends or intervals of the coil to prevent deformation or displacement of the winding.

Enhanced heat dissipation

Oil path guidance: The microchannels formed by the wrinkle structure can promote the flow of insulating oil and improve the heat dissipation efficiency.

Heat conduction medium: The thermal conductivity of paper fiber combined with insulating oil is enhanced, reducing the temperature rise of hot spots.

Partial discharge suppression

By adsorbing insulating oil to form a uniform oil film, eliminate air gaps and reduce the risk of partial discharge.

Functional characteristics

Electrical performance

High dielectric strength: After impregnation, the dielectric strength of pure cellulose material can reach 15–25 kV/mm (related to thickness and impregnation process).

Low dielectric loss: The dielectric loss tangent (tanδ) is low under the power frequency electric field, reducing energy loss.

Mechanical properties

Flexibility: The wrinkle structure gives the material anti-bending and anti-tearing capabilities, adapting to the complex shape of the winding

Compressive strength: After impregnation, the hardness is increased, and it can withstand the long-term effects of the coil’s own weight and electromagnetic force.

Heat and aging resistance

Heat resistance level: conventional corrugated paper tubes can withstand temperatures of 105–120°C, and high-temperature impregnation types can reach 130°C (such as using heat-resistant epoxy resin).

Oil compatibility: long-term contact with mineral oil or ester oil will not cause swelling or chemical degradation.

Process compatibility

Easy to process: can be wound, cut or preformed, suitable for automated production lines.

Impregnation permeability: the corrugated structure facilitates rapid penetration of insulating oil or resin to form a dense insulating layer.

Key parameters and process of selection

The selection of crepe paper tube needs to comprehensively consider the transformer design parameters, operating environment and cost-effectiveness. The specific steps are as follows:

1. Core selection parameters

Thickness (δ):

Select according to voltage level:

Low voltage winding (≤35 kV): 0.5–1.5 mm

Medium voltage winding (66–220 kV): 1.5–3 mm

High voltage winding (≥330 kV): 3–6 mm (multi-layer composite use)

Note: It is necessary to verify whether the local field strength exceeds the standard through electric field simulation.

Wrinkle density (wrinkle rate):

The higher the wrinkle rate (such as 20–30%), the stronger the ability to absorb insulating oil, but the mechanical strength decreases slightly.

The recommended wrinkle rate for conventional applications is 15–25% (balance oil adsorption and pressure resistance requirements).

Material composition:

Cellulose purity: ≥95% (reduce partial discharge caused by impurities).

Impregnant type: must be compatible with transformer oil (such as epoxy resin, acrylate).

Temperature resistance level:

Conventional oil-immersed transformers: select 105°C (Class A) or 130°C (Class E) temperature resistance models.

Overload or high temperature environment: H-class (180°C) materials (such as Nomex® composite paper tubes) are required.

2. Selection process

Determine the application scenario:

Different locations such as winding interlayer insulation, lead sleeves, and end pads have different requirements for paper tube performance.

For example: lead sleeves require higher mechanical strength, and interlayer insulation requires higher dielectric strength.

Matching voltage level:

Calculate the required paper tube thickness based on the insulation distance (oil-paper composite insulation), referring to standards such as IEC 60641 or GB/T 5591.3.

Environmental conditions to be assessed:

Wet and hot environment: Moisture-proof corrugated paper (such as silane coupling agent coating) should be selected.

High vibration scenario: High tensile strength models (such as longitudinal tensile strength ≥ 80 MPa) should be preferred.

Compatibility verification:

Compatibility test with insulating oil (such as IEC 60814 aging test) to ensure long-term operation without precipitation.

Chemical reactivity test with epoxy resin or curing agent (dry composite insulation scenario).

Cost and environmental considerations:

Ordinary models have low cost, but high-priced composite materials (such as aramid paper) are required for high temperature or special environment.

Environmental regulations must be met (such as EU RoHS restrictions on halogen content).

3. Typical selection cases

Case 1: 66 kV oil-immersed distribution transformer

Selection parameters: thickness 2 mm, wrinkle rate 20%, temperature resistance 105°C, cellulose purity 98%.

Application location: winding interlayer insulation and lead bushing.

Case 2: 500 kV ultra-high voltage transformer

Selection parameters: thickness 4 mm (multi-layer composite), wrinkle rate 15%, temperature resistance 130°C (epoxy impregnation).

Special requirements: need to pass the partial discharge test (≤5 pC) and lightning impulse withstand test.

Common problems and optimization directions

Problem 1: Moisture absorption leads to insulation degradation

Optimization solution: use vacuum impregnation process, or apply hydrophobic coating (such as fluorination treatment) on the surface of paper tube.

Problem 2: Mechanical strength decreases after long-term oil immersion

Optimization solution: use high-density cellulose paper or composite reinforcement materials (such as glass fiber interlayer).

Corrugated paper tubes are irreplaceable insulation and structural materials in oil-immersed transformers. Their selection needs to comprehensively consider electrical performance, mechanical strength, environmental adaptability and cost factors. With the development of high-voltage and large-capacity transformers, high-temperature-resistant, composite-reinforced corrugated paper tubes will become the mainstream, and the integration of environmental protection and intelligent technologies will promote their further upgrading.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations