G10 Epoxy Fiberglass Sheet

NEMA G-10/EPGC201/HGW2372/EP1 Epoxy Fiberglass Laminated Board

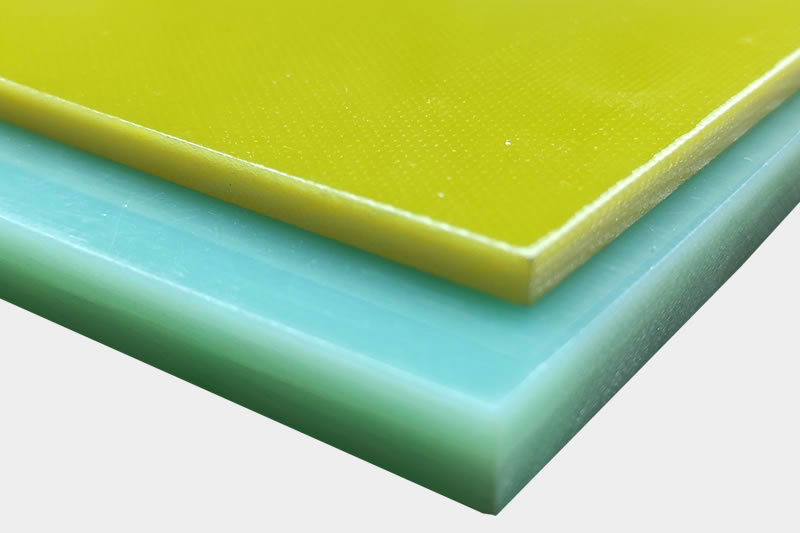

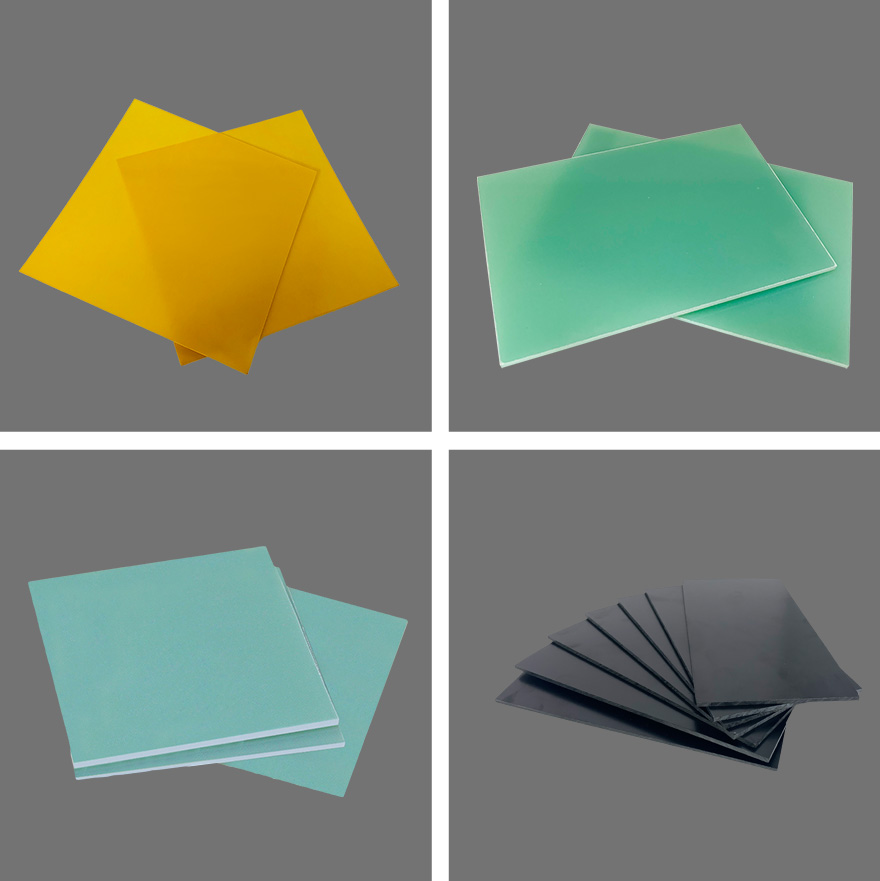

Color: Green/Water Green/White/Yellow

Thickness: 0.1-100mm

Size:1020*1220 /1020*1020 /1220*2440 /1220*2040 mm(support customize)

Heat resistance rating: Class B (130° C)

Free Samples!

Leave us a message to get quotation and sample!

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it.

Product Introduction

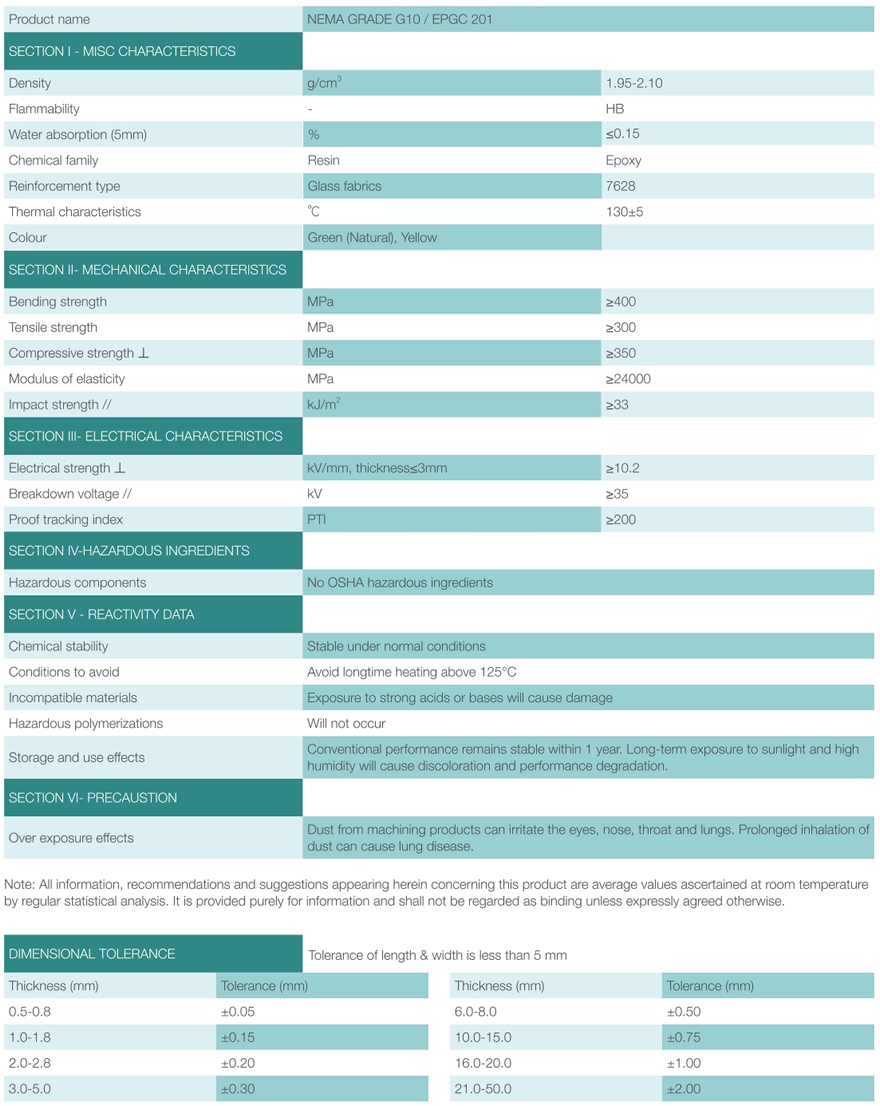

G10 Epoxy Fiberglass Laminated Sheet(EPGC 201/NEMA G-10/HGW2372/EP1) IEC:EPGC201,JIS:EL-GEH,NEMA:G10

G10 high temperature epoxy resin fiberglass board is created by compressing fiberglass cloth, soaked in high temperature resistant epoxy resin under heat with excellent mechanical and dielectric properties, good mechanical performance at high temperature and high humidity condition, and good processability.

■ The insulation class: class B(130°C)

■ The main color is yellow,green, black.

■ Standard:IEC60893-3:2003

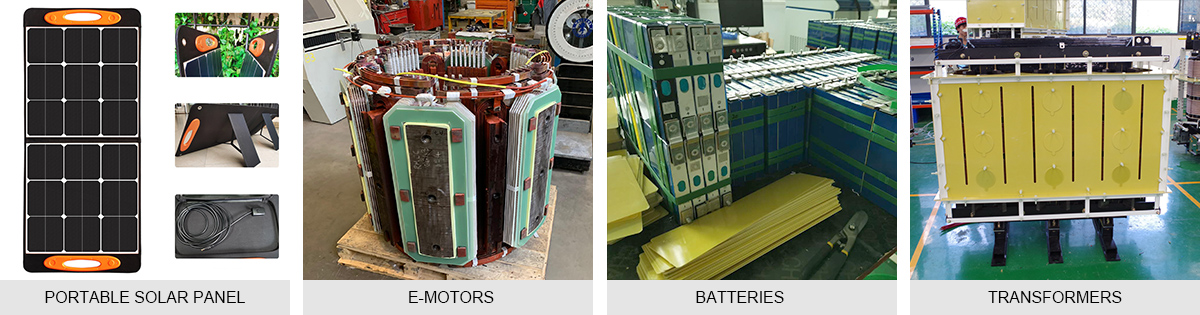

G10 sheet Application:

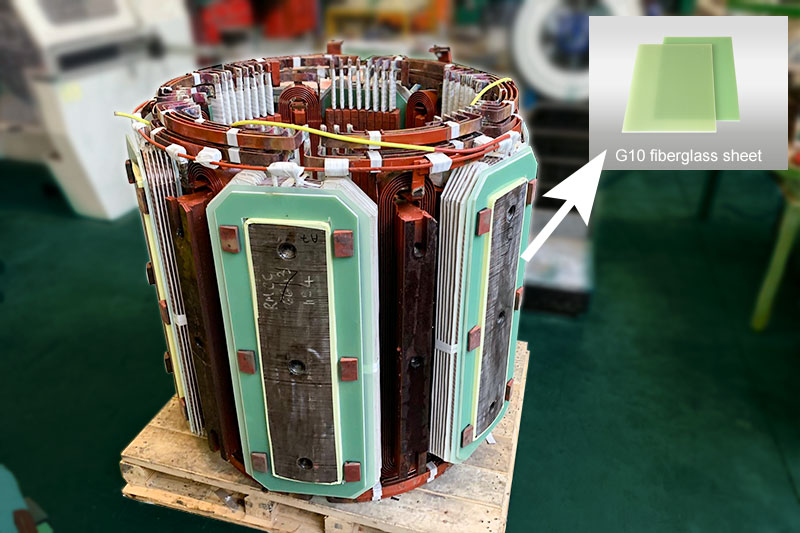

In motors, G10 is primarily used in the following ways:

1.Insulation Components

The core function of G10 in motors is electrical insulation, and it’s widely used in internal structural parts such as:

Slot wedges: Secure the stator winding coils in the slots of the iron core, preventing displacement due to vibration or electromagnetic force.

End insulation plates: Prevent short circuits between windings or between the winding and the core.

Phase insulation boards: Separate windings of different phases in multi-phase motors to avoid inter-phase short circuits.

Interlayer insulation / Insulating spacers: Provide insulation between winding layers in the stator or rotor.

2. Structural Support and Reinforcement

Due to its high mechanical strength, G10 is also used for:

Support rings or reinforcement rings: Provide structural support to the windings, resisting deformation caused by centrifugal forces during high-speed rotation.

Bearing seats or thermal insulation pads: Assist in thermal management and structural integrity within the motor.

3. Thermal Insulation in Stator/Rotor

In high-temperature motors or environments requiring thermal isolation, G10 (rated to Class B or higher, up to 130°C+) is used as thermal insulation or heat shields.

4. Mounting Bases for Brushes and Conductive Parts

Thanks to its excellent machinability and dimensional stability, G10 is suitable for use as:

Non-conductive mounting bases for brushes, brush holders, or slip rings

Mounting boards for relays, contactors, or other control components within the motor housing

Summary of G10 sheet Advantages in Motor Applications

| Property | Function |

| Excellent electrical insulation | Ensures motor safety and prevents short circuits |

| High mechanical strength | Provides structural support and resists impact/vibration |

| Good thermal resistance | Performs reliably in high-temperature environments |

| Moisture and chemical resistance | Suitable for humid or corrosive settings |

| Good machinability | Easily cut, drilled, and milled into complex shapes |

G10 sheet More Applications

| Slot Wedges | Machine parts | Transformer baffles |

| Terminal Boards and Tag Strips | Bolt Insulation | Electromechanical Components |

| High-Voltage Switches | FPC Reinforcing Sheets | Wiring Boards |

| Planetary Gears | Electronic Insulation Fields | Power Distribution Cabinets |

G10 Epoxy Fiberglass Sheet Parameter:

G10 Sheet Warehouse and packaging

Application of Nema G10 High Temperature Epoxy Resin Fiberglass sheet

It can be used as insulating structural parts with heat resistance for electrical equipments such as circuit breakers, switchgear, transformers, DC motors, AC contactors, explosion-proof electrical appliances, electric furnace, electric melting furnace, etc.

It can also be used for making structural support parts of switch and transformer, bus clamp plate, signal plate, partitions and lining plates of various switch gears, terminal plate, interphase insulation, bottom baffle, contact support parts, movable cover, slot wedge stator, fixed gasket, thin gasket, carbon brush, etc.

G10 sheet More Applications

| Slot Wedges | Machine parts | Transformer baffles |

| Terminal Boards and Tag Strips | Bolt Insulation | Electromechanical Components |

| High-Voltage Switches | FPC Reinforcing Sheets | Wiring Boards |

| Planetary Gears | Electronic Insulation Fields | Power Distribution Cabinets |

FR4 VS G10

1.The color, parameter and properity is similar between g10 and fr4

2.The difference is fr4 with flame retardant properties, and the flame retardant grade is UL94-V0 grade (after 10 seconds of burning test, the flame is extinguished within 30 seconds, no burning matter falls). G10 is not.

3.FR-4 is the grade most widely in use today. G-10, the predecessor to FR-4, lacks FR-4’s self-extinguishing flammability characteristics. Hence, FR-4 has since replaced G-10 in most applications

Our Certificates

We are steadily growing upinto aleading enterpriseof electrical equipment with an international brand in China.We are IS09001,IS014001and 0HSAS18000 certified.With 65 years’experience,a sound quality control system and the consummate after-sales service,we win a high reputation both at home and abroad.

Our Customer Cases

Why Choose ZTelec Group’s G10 Epoxy Sheet

1、 Automatic Coating: Glue evenly, strictly control PP sheet move.

2、 Fully automatic special equipment: Without one machine multi-purpose, which can guarantee product quality stability.

3、 Quality testing: Strict factory inspection, total quality management TQM

4、 Processing Service: According to your requirements, we process and customize on time and quality

5、UL,SGS and ROSH certificates are complete, and sample testing can be provided

PDF DOWNLOAD: G10 Fiberglass Laminates data sheet

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778