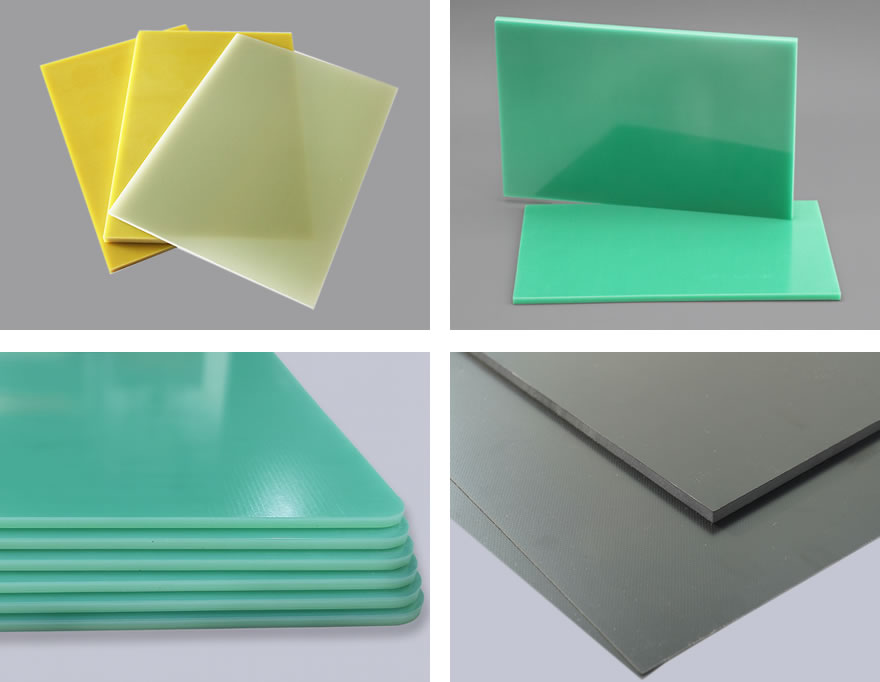

Bakelite Board Electrical Insulation Material

Bakelite Board Introduction Bakelite Board (English: Phenolic Laminate Board or Bakelite Board) is a thermoset...

Bakelite Board Introduction

Bakelite Board (English: Phenolic Laminate Board or Bakelite Board) is a thermosetting plastic sheet made by laminating phenolic resin (phenol-formaldehyde resin) under high temperature and pressure.

Historical Background: Invented in 1907 by Belgian chemist Leo Baekeland, it was the world’s first synthetic plastic and was widely used in early electrical and industrial applications.

Core Components:

Base Materials: Paper, cotton cloth, fiberglass, etc. (different base materials determine performance variations).

Resin: Phenolic resin (provides high insulation, heat resistance, and mechanical strength).

Bakelite Manufacturing Process

The production of Bakelite board involves the following steps:

1. Raw Material Preparation

Base Material Treatment: Paper or cloth substrates are dried and impregnated with phenolic resin solution.

Resin Formulation: Phenolic resin is mixed with curing agents and fillers (e.g., wood flour, mineral powder) to adjust viscosity and curing speed.

2. Lamination and Molding

Layer Stacking: Resin-impregnated base materials are layered (thickness determined by the number of layers).

Hot Press Curing: Molded under high temperature (140–160°C) and pressure (5–10 MPa) to cross-link and solidify the resin into a dense structure.

3. Post-Processing

Cutting and Trimming: Cut into standard sizes or custom shapes.

Surface Treatment: Polishing, grinding, or coating with insulating varnish to enhance weather resistance and aesthetics.

Bakelite Key Properties

Bakelite board exhibits the following core characteristics due to its composition and manufacturing:

| Property | Performance |

|---|---|

| Electrical Performance | High insulation resistance (10^12–10^14 Ω·cm), excellent arc resistance, suitable for high-voltage equipment. |

| Heat Resistance | Continuous use temperature: 120–140°C; short-term tolerance up to 180°C (cloth-based > paper-based). |

| Mechanical Strength | High compressive strength (cloth-based: up to 200 MPa), wear-resistant, and impact-resistant. |

| Chemical Stability | Resistant to weak acids, alkalis, and organic solvents, but corrodes in strong acids/alkalis. |

| Machinability | Drillable, millable, and lathe-turning compatible, but generates dust during processing (requires protective gear). |

Bakelite Applications

Bakelite board is widely used in the following fields due to its versatile properties:

1.Electrical and Electronics Industry

Insulating Components: Circuit breakers, switches, terminal blocks, transformer insulating spacers.

Circuit Substrates: Early PCB (printed circuit board) base material, now largely replaced by epoxy resin boards.

2. Mechanical Manufacturing

Wear-Resistant Parts: Gears, bearing bushings, guide rail pads (utilizing low friction coefficient).

Tooling Fixtures: Insulating jigs, positioning blocks in machining.

3. Consumer Goods and Decoration

Handles and Casings: Electric iron handles, vintage radio casings (classic Bakelite applications).

Decorative Laminates: Wood-grain surfaces for furniture veneers.

4. Specialized Fields

Aerospace: High-temperature insulation components (requires fiberglass-reinforced Bakelite).

Rail Transit: Motor insulation pads, electrical cabinet partitions.

Common Types and Selection Guide

| Type | Base Material | Features | Typical Applications |

|---|---|---|---|

| Paper-Based Bakelite | Impregnated paper | Low cost, easy machining, moderate strength | Low-voltage insulation, general fixtures |

| Cloth-Based Bakelite | Cotton/fiberglass cloth | High strength, heat resistance | Gears, bearings, high-voltage equipment |

| Fiberglass Bakelite | Fiberglass cloth | High temperature resistance (180°C), chemical corrosion resistance | Aerospace, chemical equipment |

Limitations and Alternative Materials

Limitations:

Brittle; prone to UV-induced aging over time.

Poor environmental compatibility (formaldehyde emissions; gradually replaced by epoxy/PET boards).

Modern Alternatives:

Epoxy Resin Boards: Higher heat resistance and eco-friendliness.

Polyimide (PI): Suitable for extreme temperatures (>260°C).

Summary

As a classic insulating material, Bakelite board remains irreplaceable in medium-low voltage electrical systems and mechanical wear-resistant parts. Selection should align with temperature resistance, strength, and cost requirements, while prioritizing machining safety and environmental compliance.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-05 2026Insulation Raw Materials — Epoxy Resin Price Increase

- 03-05 2026NMN Flexible Insulation Material for Motor Winding

- 03-04 2026G11 Epoxy Glass Laminate for Generator Insulation

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment