The difference between G7 silicone glass cloth board and fr4 and g10 board

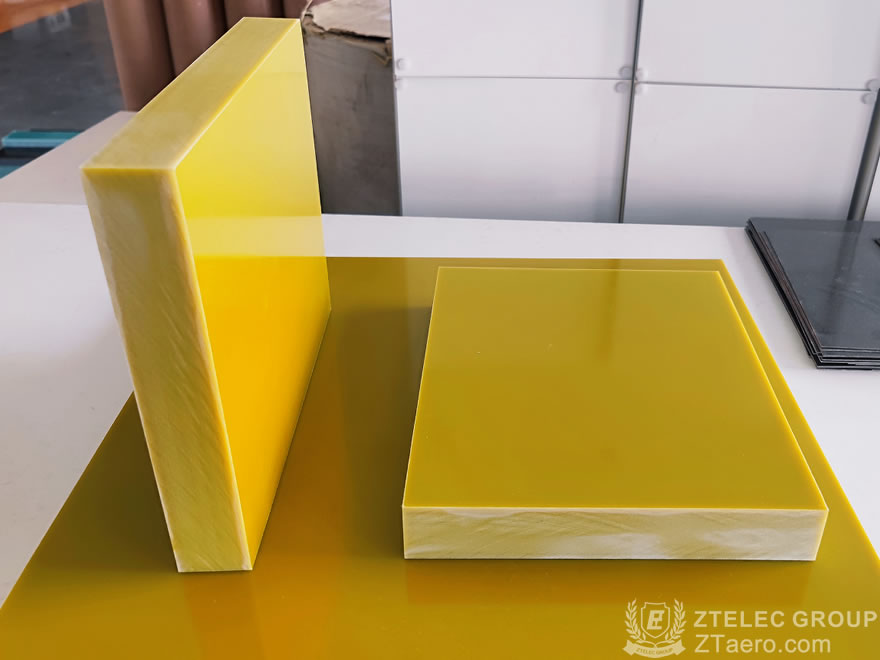

G7 silicone glass cloth board Introduction G7 Silicone Glass Cloth Laminated board is a high-performance composite m...

G7 silicone glass cloth board Introduction

G7 Silicone Glass Cloth Laminated board is a high-performance composite material formed by impregnating alkali-free glass fiber fabric with high-temperature vulcanized silicone rubber, followed by curing under high temperature and pressure. This material combines the high strength and corrosion resistance of glass fiber with the high-temperature endurance, insulation properties, and flexibility of silicone rubber, making it widely applicable in industrial fields requiring extreme environmental tolerance and reliability.

Core Composition

Glass Fiber Fabric (reinforcement skeleton) + Silicone Rubber (matrix material)

Process Characteristics

High-temperature vulcanization ensures strong bonding between silicone rubber and glass fiber, forming a stable laminated structure.

Key Advantages

Maintains stable performance under complex conditions including high temperatures, high voltage, and chemical corrosion.

Product Features

High-Temperature Resistance

Continuous operating temperature: -60°C to +250°C

Short-term tolerance: >300°C

Stable silicone molecular chains resist decomposition at elevated temperatures, outperforming conventional rubbers.

Superior Electrical Insulation

Dielectric strength: ≥20 kV/mm

Low dielectric loss (≤0.003) in high-frequency environments

Ideal for high-voltage equipment insulation components.

Balanced Mechanical Strength & Flexibility

Tensile strength (ASTM D638):

Longitudinal: ≥150 MPa

Transverse: ≥120 MPa

Tear-resistant woven glass fiber structure combined with silicone matrix elasticity.

Chemical Corrosion Resistance

Resists weak acids, alkalis, oils, and solvents (e.g., ethanol, acetone).

Avoid exposure to strong oxidizers (e.g., concentrated sulfuric acid).

Eco-Friendly & Safety Compliance

Meets RoHS and UL94 V-0 flame-retardant standards.

No molten drips and low smoke toxicity during combustion.

Machinability

Supports secondary processing: die-cutting, stamping, drilling.

Customizable dimensions (common thickness: 0.5–10 mm).

G7 board Applications

1.Power Electronics

Insulating gaskets: Interlayer isolation in transformers/circuit breakers.

Motor slot wedges: Corona resistance extends high-voltage motor lifespan.

PCB support plates: High-frequency circuit board substrates minimize signal loss.

2.Aerospace

Engine bay cable wraps: Withstand 250°C environments.

Satellite thermal insulation: Prevents brittleness from thermal cycling in vacuums.

3.New Energy & Rail Transit

EV battery pack thermal spacers.

High-speed train motor insulation liners: Endure vibration and thermal shocks.

4.Industrial Equipment

Hot press platens: Repeated high-temperature/pressure resistance (e.g., PCB lamination).

High-temperature conveyor belts: Non-stick surfaces for food processing.

5.Specialized Protection

Welding curtains: Replace asbestos with spark-resistant barriers.

Lab corrosion-resistant mats: Protect surfaces from chemical reagents.

Differences Between G7, FR4, and G10 Boards

1.Material Composition and Manufacturing Process

| Feature | G7 Silicone Glass Cloth Board | FR4 Board | G10 Board |

|---|---|---|---|

| Base Material | Alkali-free glass fiber cloth | Electronic-grade glass fiber cloth | High-strength glass fiber cloth |

| Resin | High-temperature vulcanized silicone rubber | Flame-retardant epoxy resin (brominated) | Non-flame-retardant or modified epoxy resin |

| Process | Silicone impregnation + high-temperature lamination | Epoxy impregnation + high-pressure lamination | Epoxy impregnation + high-pressure lamination (higher resin content) |

Key Differences:

G7 uses silicone rubber as the matrix, providing elasticity; FR4/G10 are rigid epoxy-based.

FR4 contains flame retardants (e.g., brominated epoxy), while G10 typically lacks flame resistance (though formulations may vary).

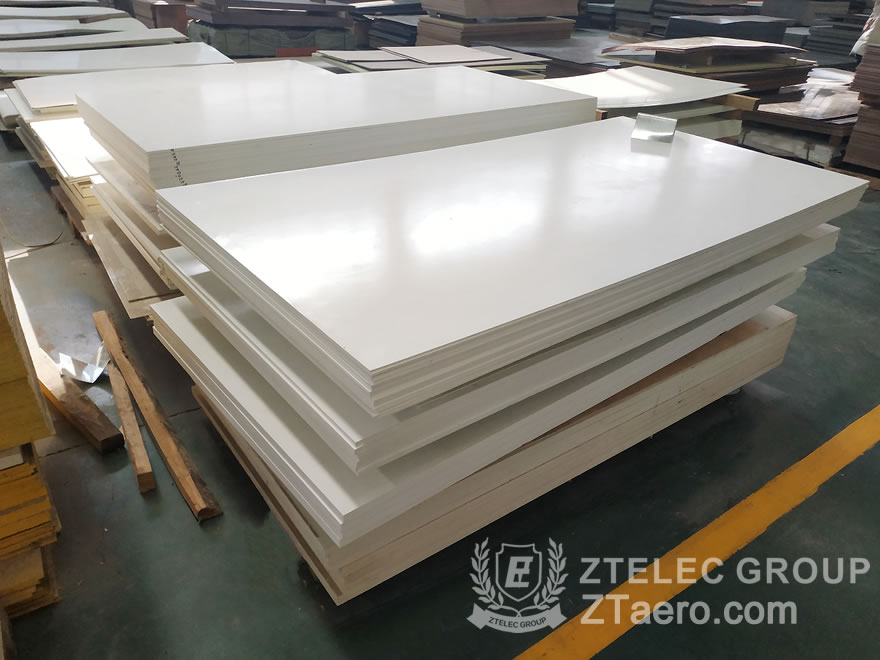

FR4 epoxy fiberglass sheet

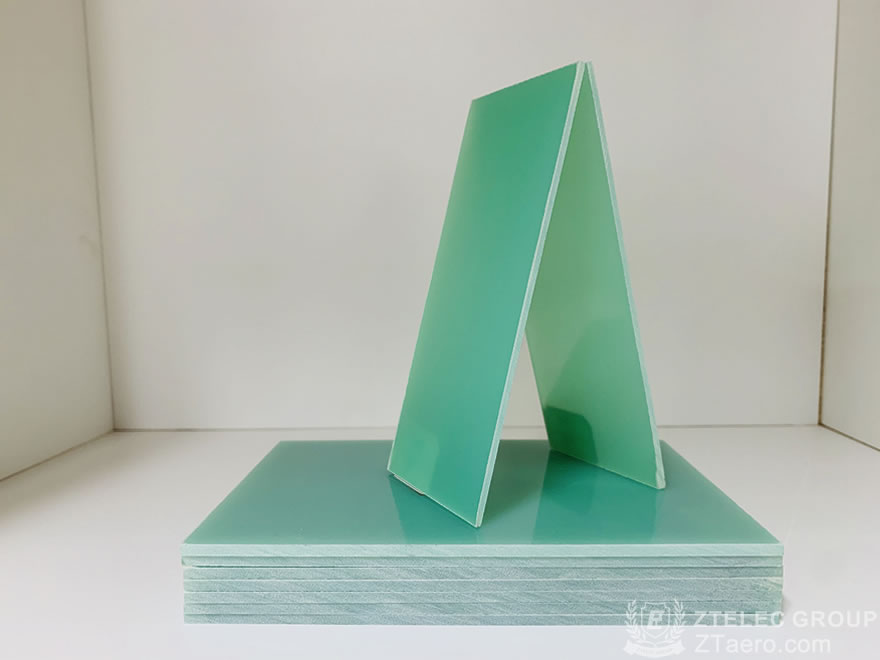

G10 epoxy fiber glass sheet

2.Core Performance Comparison

| Performance Metric | G7 Board | FR4 Board | G10 Board |

|---|---|---|---|

| Temperature Resistance | -60℃~250℃ (long-term) | -50℃~130℃ (long-term) | -50℃~150℃ (short-term peak) |

| Flame Resistance Rating | UL94 V-0 (self-extinguishing) | UL94 V-0 (flame-retardant) | UL94 HB (non-flame-retardant or low flame resistance) |

| Dielectric Strength | ≥20 kV/mm | ≥15 kV/mm | ≥18 kV/mm |

| Dielectric Loss | ≤0.003 (1 MHz) | 0.02~0.03 (1 MHz) | 0.015~0.025 (1 MHz) |

| Tensile Strength | Longitudinal ≥150 MPa | Longitudinal ≥300 MPa | Longitudinal ≥400 MPa |

| Flexibility | High (bendable for installation) | Low (brittle, prone to cracking) | Low (high rigidity) |

| Chemical Resistance | Resists weak acids, alkalis, oils | Resists weak acids; poor resistance to strong alkalis/solvents | Resists weak acids/alkalis; poor resistance to strong oxidizers |

| Density | 1.8~2.0 g/cm³ | 1.8~1.9 g/cm³ | 1.9~2.1 g/cm³ |

Key Differences:

Temperature Resistance: G7 > G10 > FR4 (silicone excels in high-temperature stability).

Mechanical Strength: G10 > FR4 > G7 (epoxy resins offer higher rigidity).

High-Frequency Performance: G7 has the lowest dielectric loss, ideal for high-frequency circuits; FR4/G10 exhibit higher losses, suitable for standard circuits.

3.Typical Applications

| Application Field | G7 Board | FR4 Board | G10 Board |

|---|---|---|---|

| Electronics & Electrical | High-frequency circuit substrates, high-voltage insulation pads | PCB substrates, general circuit insulation | High-load connectors, structural supports |

| High-Temperature Environments | Motor slot wedges, hot press equipment plates | Not applicable | Limited high-temperature use (e.g., motor housings) |

| Aerospace | Engine bay cable protection, satellite thermal insulation | Standard electronic enclosures | Structural load-bearing components |

| Industrial Equipment | Corrosion-resistant seals, welding protective curtains | Control cabinet insulation panels | Robotic arm wear-resistant liners |

| New Energy | Power battery thermal insulation | Low-voltage battery supports | High-voltage battery structural supports |

Selection Advice:

High-Frequency/High-Temperature Insulation: Prioritize G7 (e.g., 5G base stations, EV motors).

Cost-Effective PCBs: Choose FR4 (best value).

High-Strength Structural Parts: Use G10 (e.g., industrial machinery components).

4. Cost and Machining Comparison

| Aspect | G7 Board | FR4 Board | G10 Board |

|---|---|---|---|

| Material Cost | High (silicone is expensive) | Low (epoxy resin is cost-effective) | Moderate to High (complex high-resin process) |

| Machining Difficulty | Easy to cut/punch (rubber elasticity) | Requires specialized tools (brittle edges) | Difficult (high hardness demands wear-resistant tools) |

| Customization | Supports thin sheets (0.5mm) & flexible designs | Standard thickness (0.2~3mm) | Thick plates (3~50mm) for structural parts |

Notes:

G7 punching requires care to avoid silicone layer delamination (prefer laser cutting).

FR4 drilling generates glass fiber dust (require protective measures).

G10 machining needs carbide tools to reduce wear.

5. Summary: Core Differences and Substitutability

| Material | Advantages | Disadvantages | Substitutability |

|---|---|---|---|

| G7 | High-temperature resistance, superior high-frequency performance, flexibility | High cost, lower mechanical strength | Irreplaceable in high-temperature scenarios |

| FR4 | Low cost, flame retardancy, PCB standardization | Poor temperature resistance, high dielectric loss | Replaceable with G10 in non-high-temperature structural applications |

| G10 | High mechanical strength, humidity resistance | No flame retardancy, difficult machining | Replaceable with metals/engineering plastics for load-bearing parts |

Final Recommendations:

High-Temperature Insulation → G7 Board

Standard Circuit Boards → FR4 Board

High-Strength Structures → G10 Board

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support