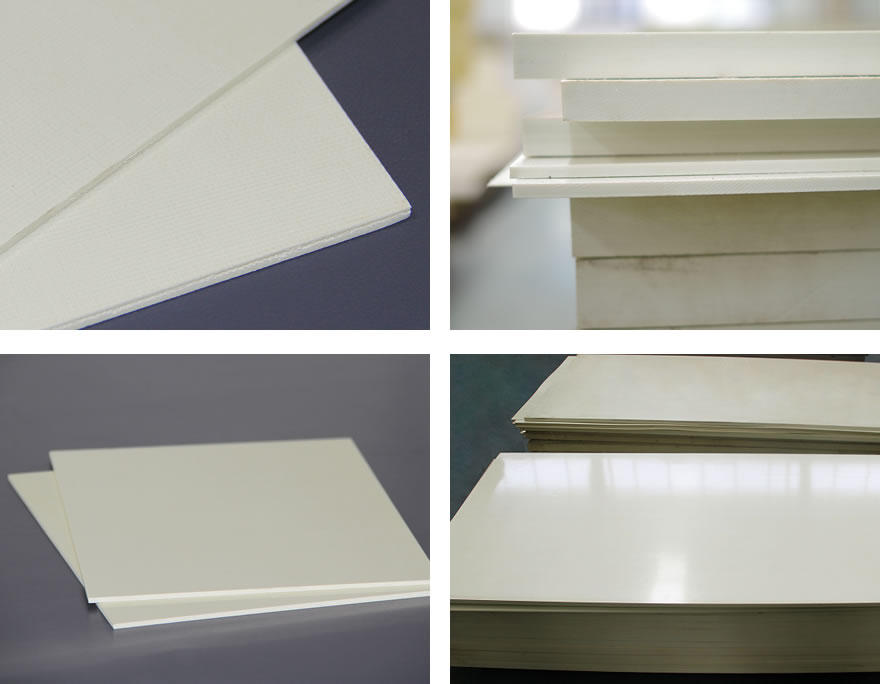

Silicone G7 laminated glass cloth Sheet Application

Product instruction Silicone G7 laminated glass cloth Sheet is a high-performance insulating material, mainly made o...

Product instruction

Silicone G7 laminated glass cloth Sheet is a high-performance insulating material, mainly made of glass cloth reinforcement and silicone resin laminated by hot pressing. It has excellent electrical insulation performance, high temperature resistance and flame retardant properties, and can work stably even in high humidity or high temperature environments.

1. Main performance characteristics :

High temperature resistance: can be used in high temperature environment of 200~220℃ for a long time

Stable electrical performance: excellent insulation even in humid and high temperature conditions

Good flame retardancy: self-extinguishing performance

Strong chemical stability: acid and alkali resistance, aging resistance

Good dimensional stability: low thermal expansion coefficient, structure is not easy to deform

2. Comparison between G7 and other glass cloth sheets:

| Type | Resin Base | Temperature Resistance | Flame Retardancy | Typical Environment |

|---|---|---|---|---|

| G7 | Silicone | 200–220°C | Excellent | High temp / Humid |

| G10 | Epoxy | 130–150°C | Moderate | General purpose |

| G11 | Modified Epoxy | ~180°C | Good | High temp |

| FR4 | Flame-retardant Epoxy | ~130°C | Excellent | General electronics |

3. Typical uses of G7 laminated glass cloth sheet:

High temperature electronic/electrical insulation

Application scenarios: insulation parts of motors, transformers, generators, and electric heating equipment.

Advantages: long-term temperature resistance up to 180°C~250°C (H grade or higher insulation grade), good flame retardancy (UL94 V0 grade), suitable for high temperature and high humidity environment.

Aerospace and military industry

Application scenarios: aircraft engine compartment insulation layer, missile fairing, spacecraft circuit substrate.

Advantages: lightweight, heat shock resistant, stable performance at extreme temperatures (-60°C to +300°C).

Rail transit

Application scenarios: electrical control systems of high-speed rail/subway, traction motor insulation boards.

Advantages: flame retardant, low smoke and non-toxic, in line with rail transit fire protection standards such as EN45545.

New energy and power equipment

Application scenarios: insulation support parts of solar inverters, wind power converters, and high-voltage switch cabinets.

Advantages: arc resistance, corona resistance, high dielectric strength (>20kV/mm).

Chemical and anti-corrosion equipment

Application scenarios: reactor lining, pipeline sealing gaskets, structural parts in corrosive environments.

Advantages: acid and alkali resistance, organic solvents and ozone resistance, excellent anti-aging performance.

High-end electronic packaging

Application scenarios: high-frequency PCB substrates (such as radar, 5G communication equipment), high-power LED heat dissipation substrates.

Advantages: low dielectric constant (Dk), low dielectric loss (Df), stable high-frequency signal transmission.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations