Phenolic cotton cloth board and phenolic paperboard Application

I. Main Differences Phenolic cotton cloth board and phenolic paper board are both phenolic resin-based composites. H...

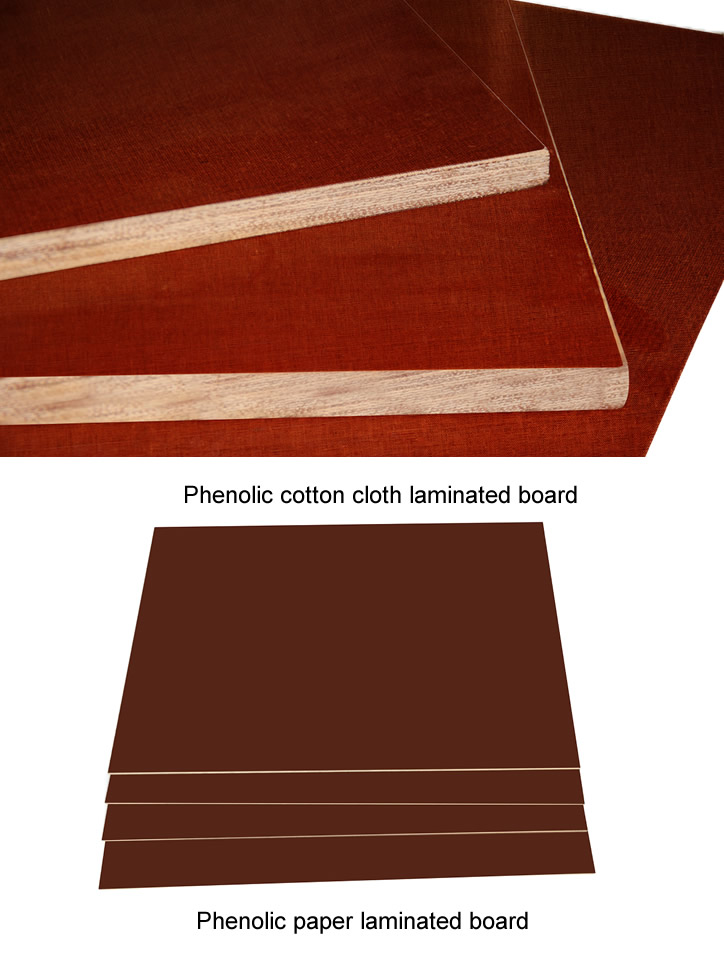

I. Main Differences

Phenolic cotton cloth board and phenolic paper board are both phenolic resin-based composites. However, due to differences in reinforcing materials (cotton cloth fibers vs. wood pulp paper fibers), their physical properties and applications vary significantly:

Phenolic Cotton Cloth Board

Reinforced with cotton cloth, its long, tightly interwoven fibers provide high mechanical strength, impact resistance, and wear resistance, though it has slightly higher moisture absorption and lower insulation performance.

Core Applications: Suitable for wear-resistant and impact-resistant components in mechanical and transportation industries (e.g., gears, bearing bushings, brake pads) and structural supports in humid environments.

Phenolic Paper Board

Reinforced with wood pulp paper, its short, uniformly distributed fibers create a denser structure, offering excellent insulation, arc resistance, and low cost, but with lower mechanical strength.

Core Applications: Dominates electrical and electronic insulation components (e.g., switchgear partitions, terminal blocks), decorative laminates in light industries, and low-end PCB substrates.

II. Comparison Table of Application Fields

| Application Field | Phenolic Cotton Cloth Board Uses | Phenolic Paper Board Uses | Key Differences |

|---|---|---|---|

| Mechanical Industry | Gears, bearing bushings, buffer layers for stamping dies | Light-duty molds, packaging spacers | Cotton cloth: High wear resistance; Paper: Low strength, cost-effective |

| Transportation | Brake pads, pantograph sliders, marine insulation supports | Automotive dashboard panels, lightweight components | Cotton cloth: Heat/impact resistance; Paper: Lightweight |

| Electrical & Electronics | Insulation parts in humid environments (requires surface treatment) | Switchgear partitions, PCB substrates, terminal blocks | Paper: Superior insulation, lower cost |

| Light Industry | Wear-resistant linings for heavy machinery | Furniture decorative laminates, instrument panels | Cotton cloth: Durability; Paper: Easy processing, aesthetics |

| Special Environments | High-temperature insulation gaskets (metallurgy), corrosion-resistant linings (chemical equipment) | Dry-environment insulation supports, low-voltage enclosures | Cotton cloth: Heat/corrosion resistance; Paper: Dry insulation |

III. Key Selection Criteria

Mechanical Requirements: Choose cotton cloth board for high-load/impact scenarios; paper board for low-cost, lightweight applications.

Insulation & Environment: Paper board for dry insulation; cotton cloth board for humid/high-temperature environments (with moisture-proof treatment).

Processing & Cost: Paper board for complex structures (easy machining); cotton cloth board for long-term durability.

IV. Summary

Phenolic cotton cloth board excels in mechanical performance, while phenolic paper board dominates in insulation and cost-effectiveness. The two materials complement each other, with selection based on specific performance requirements and environmental conditions. Practical choices should balance operational demands (mechanical, thermal, humidity) and economic factors.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations