Fiberglass Wound Tubes in Dry-Type Transformers

Product Overview Epoxy Fiberglass wound tubes—also known as fiberglass insulation tubes or epoxy glass tubes—are hig...

Product Overview

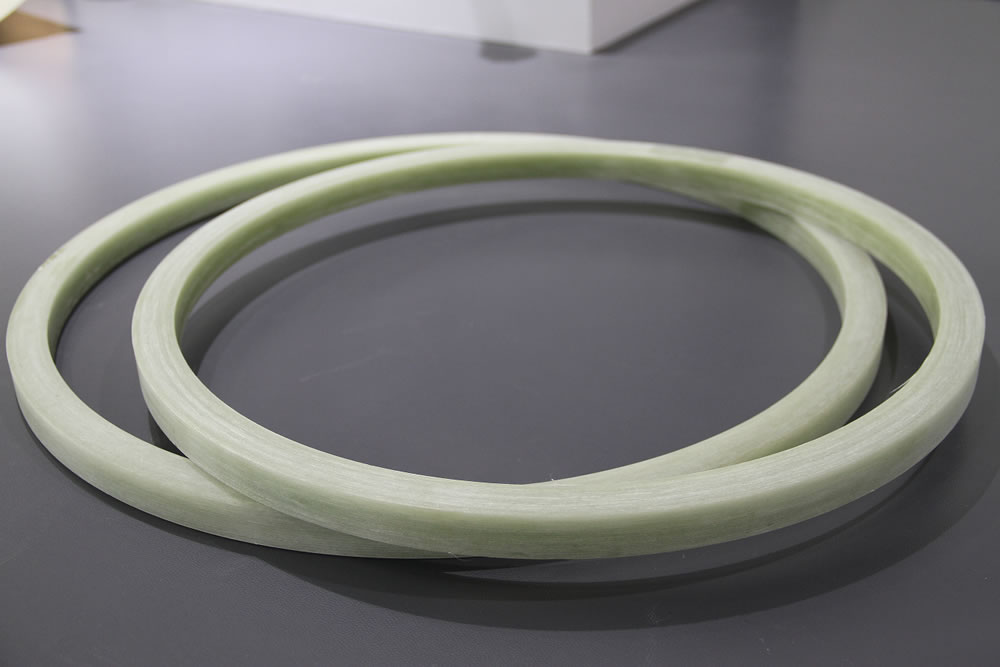

Epoxy Fiberglass wound tubes—also known as fiberglass insulation tubes or epoxy glass tubes—are high-performance insulating components made by winding fiberglass yarns impregnated with resin and curing them under heat and pressure. They offer excellent electrical insulation, mechanical strength, and thermal stability, making them ideal for use in dry-type transformers.

Key Applications in Dry-Type Transformers

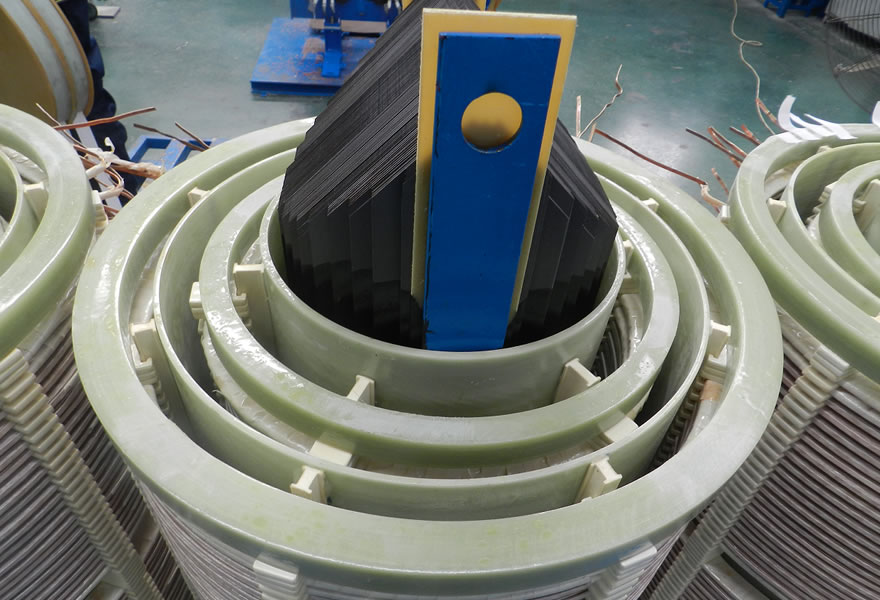

1. Coil Support and Structural Insulation

Used as spacers and support rods between high and low voltage windings.Ensures reliable coil positioning and prevents displacement or deformation under thermal and mechanical stress.

2. Lead Protection Tubes

Serves as protective sleeves for high-voltage and low-voltage lead wires.Prevents abrasion, insulation breakdown, and mechanical damage during transformer operation.

3. Core Clamping and Frame Components

Applied in iron core clamping structures or insulation frameworks.

Can be machined into various structural parts, improving overall insulation reliability compared to traditional materials like wood or cardboard.

Advantages

Performance Area Highlights

Electrical Insulation High dielectric strength; suitable for high-voltage insulation

Thermal Resistance Supports continuous operation at high temperatures (up to Class F/H)

Mechanical Strength Excellent compression and impact resistance; stable under stress

Machinability Easily cut, drilled, and machined to customized shapes

Environmental Resistance Moisture-proof, anti-corrosive, suitable for harsh environments

Selection Guidelines

When choosing fiberglass wound tubes for dry-type transformers, consider the following:

Inner Diameter & Wall Thickness: Should match the spacing or wire size in the transformer.

Temperature Class: Choose F-class (155°C) or H-class (180°C) materials as required.

Resin Type: Epoxy resin tubes for high mechanical performance; phenolic resin tubes for flame resistance and low loss.

Standards Compliance: Prioritize products certified by international standards such as UL, IEC, or ASTM.

Conclusion

Fiberglass wound tubes are a critical component in modern dry-type transformers, providing durable, safe, and high-performance insulation. Their ability to withstand thermal, electrical, and mechanical stress ensures reliable transformer operation in demanding environments.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations