GPO-3 vs G-10 Material Comparison

The difference between GPO-3 and G-10 Material The terms GPO-3 and G-10 (or G10) refer to two distinct types of glas...

The difference between GPO-3 and G-10 Material

The terms GPO-3 and G-10 (or G10) refer to two distinct types of glass-reinforced thermoset laminate materials, commonly used in electrical, mechanical, and structural applications. While they share similarities (both are fiberglass composites), their base resins, properties, and primary applications differ significantly.

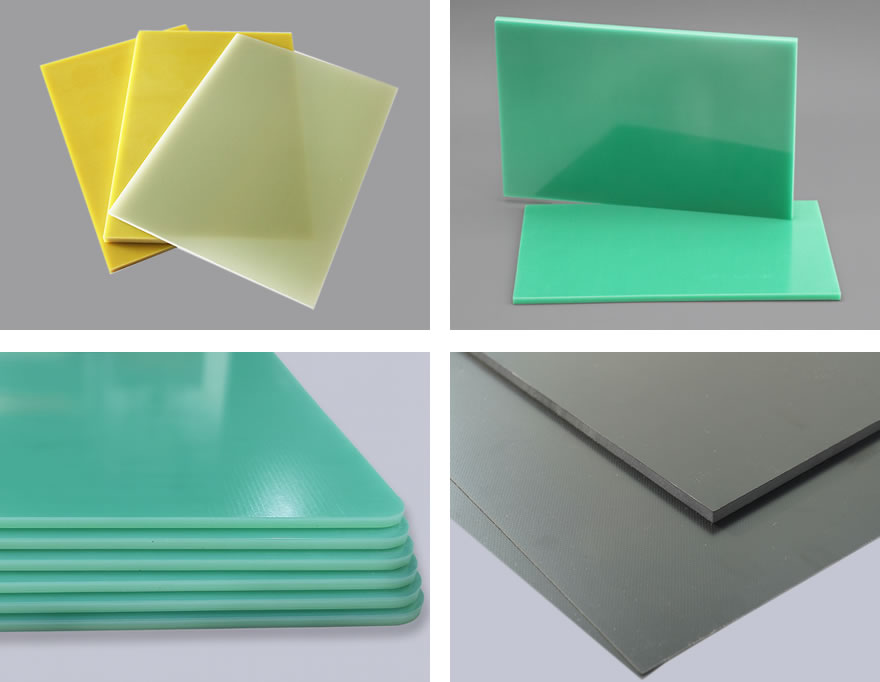

GPO 3 material

GPO-3 vs G-10 Material Comparison

| Property | GPO-3 | G-10 / FR4 |

|---|---|---|

| Base Resin | Polyester resin | Epoxy resin |

| Key Characteristic | Flame-retardant, arc-resistant | High mechanical strength, moisture-resistant |

| Flame Performance | Self-extinguishing (meets UL 94 V-0) | Not inherently flame-retardant |

| Arc Resistance | Superior (resists carbon tracking) | Good, but less than GPO-3 |

| Mechanical Strength | Moderate (lower than G-10) | Very high (stiff & strong) |

| Moisture Resistance | Good | Excellent |

| Electrical Insulation | Good (especially in harsh conditions) | Excellent (stable in humid environments) |

| Thermal Capability | Continuous: ~130°C, Peak: ~155°C | Continuous: ~140°C, Peak: ~180°C |

| Cost | Lower | Higher |

| Primary Applications | Switchgear, motor components, arc shields | PCBs, precision insulators, structural parts |

Key Differences Explained:

Resin Chemistry:

GPO-3: Uses a polyester resin (often specifically formulated for flame retardancy and arc resistance).

G-10: Uses an epoxy resin. This gives G-10 superior mechanical strength, dimensional stability, and moisture resistance compared to polyester-based laminates.

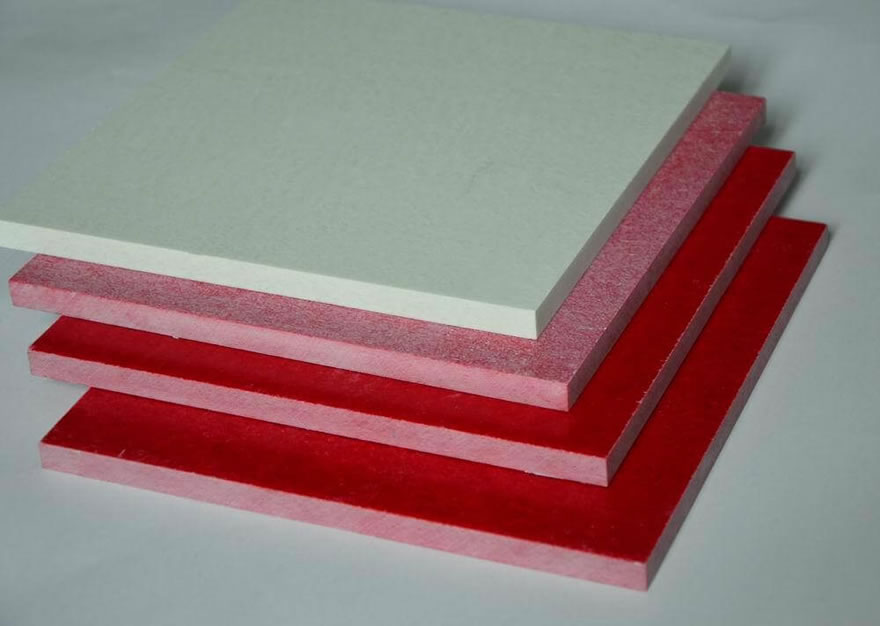

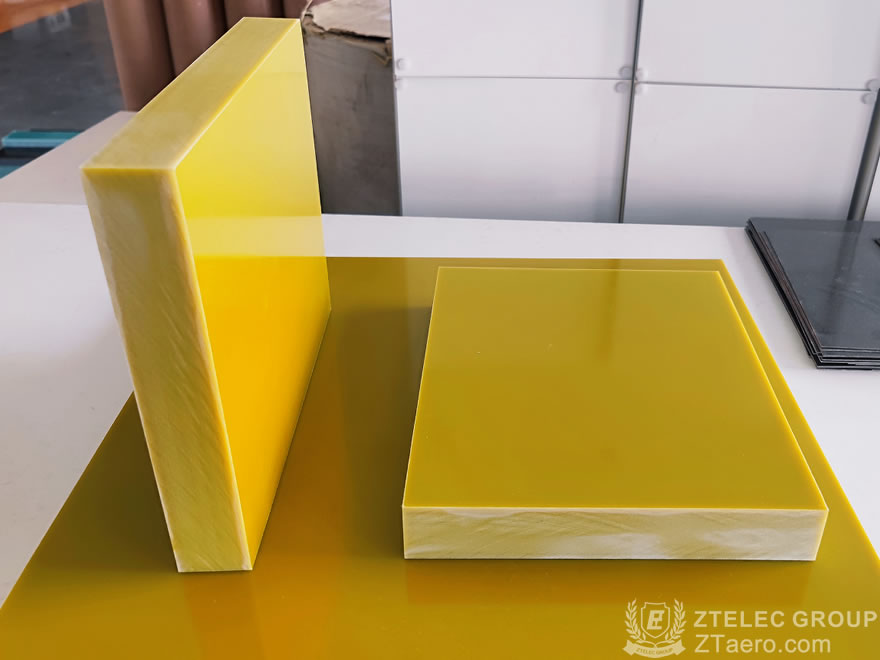

G10 Material

Flame Retardancy & Arc Resistance:

GPO-3: This is its defining characteristic. GPO-3 is specifically engineered to be self-extinguishing (typically meeting UL 94 V-0) and offers excellent resistance to electrical arc tracking (the formation of conductive carbon paths on the surface during arcing). This makes it ideal for electrical components where fire safety and arc faults are major concerns.

G-10: Standard G-10 is NOT inherently flame-retardant. While it has good electrical insulation properties, it can burn if exposed to sufficient flame. For flame-retardant applications requiring epoxy’s properties, FR4 (the flame-retardant version of G-10, meeting UL 94 V-0) is used instead. G-10/FR4 has good arc resistance, but generally not as high as GPO-3 specifically designed for that purpose.

Mechanical Strength & Rigidity:

G-10: Offers significantly higher tensile, flexural, and compressive strength, as well as better rigidity (stiffness) than GPO-3. The epoxy resin bonds more effectively with the glass fibers.

GPO-3: Has moderate mechanical strength, sufficient for many electrical applications, but generally lower than G-10. It’s less stiff.

Moisture Absorption & Resistance:

G-10: Has very low moisture absorption due to the epoxy resin. This makes it highly stable in humid environments and maintains its electrical properties well under such conditions.

GPO-3: Has good moisture resistance (better than many non-reinforced plastics), but typically higher absorption than G-10. While still suitable for many electrical uses, prolonged exposure to high humidity can have a slightly greater impact on properties.

Electrical Insulation:

Both offer excellent electrical insulation properties for their intended uses.

G-10/FR4: Provides exceptional electrical insulation with high stability, making it the dominant material for printed circuit boards (PCBs).

GPO-3: Provides very good electrical insulation, particularly excelling in environments prone to arcing and tracking, where its flame-retardant properties are critical.

Thermal Capability:

G-10: Generally has a slightly higher continuous operating temperature (often rated around 130-140°C / 266-284°F) and higher peak temperature tolerance than standard GPO-3.

GPO-3: Continuous operating temperature is typically around 105-130°C (221-266°F), depending on the specific grade.

Cost:

GPO-3: Generally less expensive than G-10/FR4.

G-10/FR4: Typically more expensive due to the epoxy resin and its superior mechanical properties.

Summary & When to Choose Which:

Choose GPO-3 when:

Flame retardancy (UL 94 V-0) is mandatory.

High arc resistance and tracking resistance are critical (e.g., barriers in switchgear, arc chutes, motor slot wedges, terminal boards in high-energy circuits).

Good general electrical insulation is needed in a potentially harsh environment.

Cost is a significant factor, and the highest mechanical strength isn’t required.

Choose G-10/FR4 when:

Superior mechanical strength, rigidity, and dimensional stability are required.

Very low moisture absorption and excellent electrical stability in humid conditions are critical.

Manufacturing printed circuit boards (PCBs) – FR4 is the standard.

Precision machined structural or insulating parts (e.g., spacers, bushings, insulators) where tight tolerances and strength are paramount.

Flame retardancy is needed (use FR4, not standard G-10).

In essence: GPO-3 prioritizes fire safety and arc protection, while G-10/FR4 prioritizes mechanical strength, moisture resistance, and dimensional stability (with FR4 adding flame retardancy). They are complementary materials serving different primary needs within the electrical and industrial laminate market.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-05 2026Insulation Raw Materials — Epoxy Resin Price Increase

- 03-05 2026NMN Flexible Insulation Material for Motor Winding

- 03-04 2026G11 Epoxy Glass Laminate for Generator Insulation

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment