Transformer Pressboard Spacers Detailed Explanation

Product Introduction Transformer pressboard spacers are critical insulating components used in oil-immersed tr...

Product Introduction

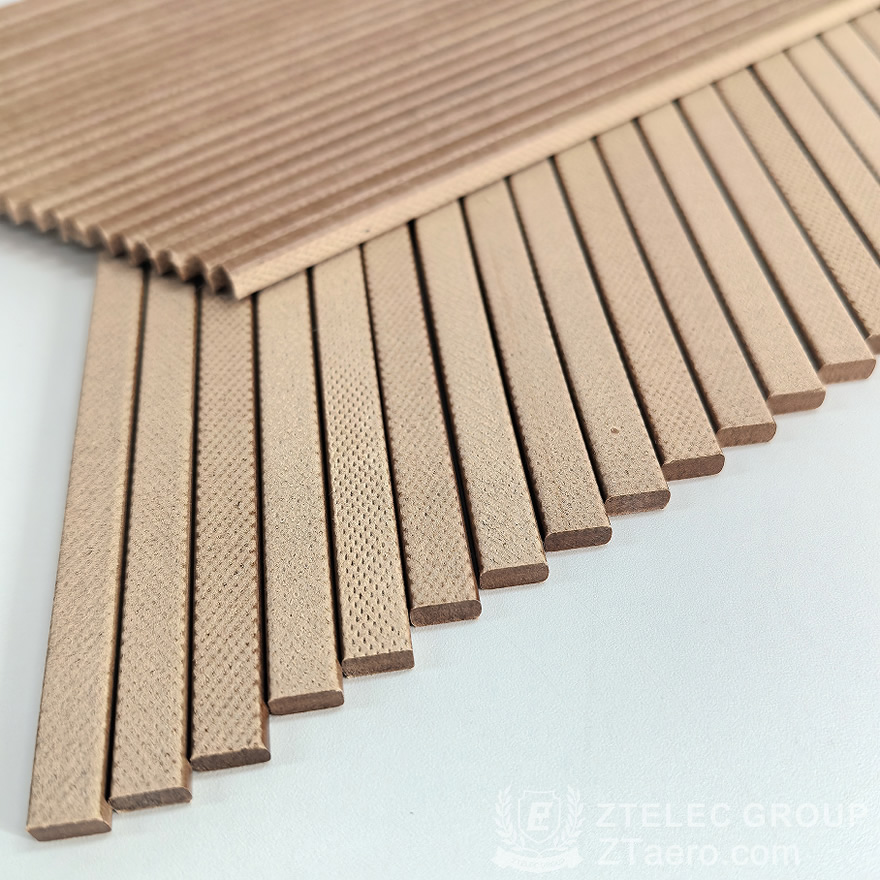

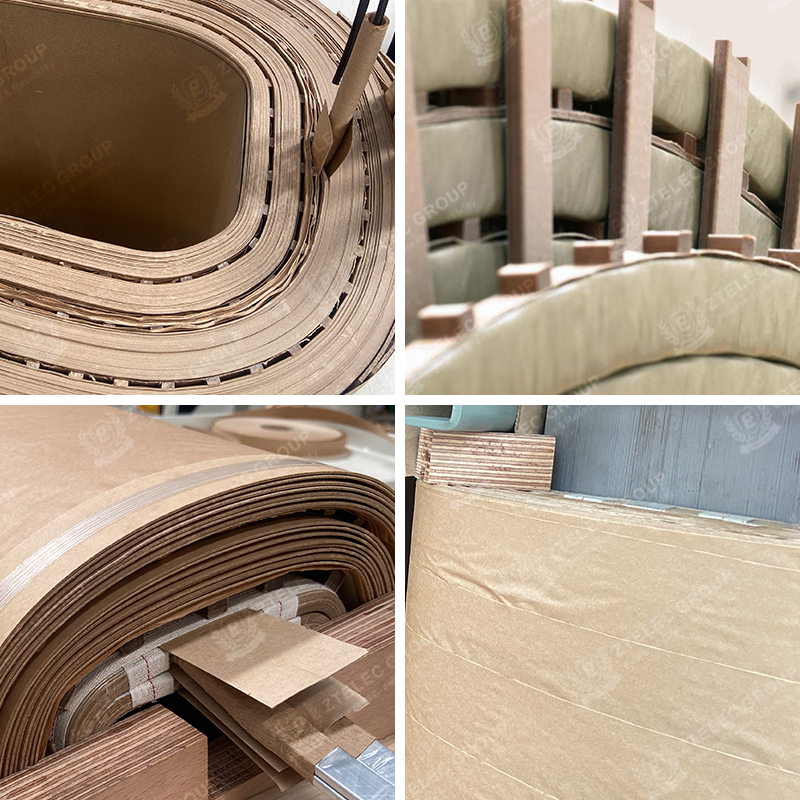

Transformer pressboard spacers are critical insulating components used in oil-immersed transformers, primarily made of insulating laminated pressboard (e.g., T4, T3 grades). The raw material is sulfate wood pulp, processed under high temperature and pressure to form a dense structure. These spacers are typically elongated strips with rectangular or trapezoidal cross-sections, often featuring chamfered or rounded edges to minimize electric field distortion and enhance insulation reliability. They are precisely positioned between winding layers, windings, and the core, serving three key functions: insulation, heat dissipation, and mechanical support.

Transformer Pressboard Spacers Core Characteristics

Electrical Performance

Dielectric strength ≥10 kV/mm (in oil), volume resistivity >10¹² Ω·cm, ensuring insulation safety under high voltage.

Mechanical Performance

Compressive strength >100 MPa, elastic modulus ≥5 GPa, capable of withstanding electromagnetic forces up to tens of kN/m² during short-circuit events.

Thermal Stability

Long-term tolerance: 105°C (Class A) or 120°C (Class E); short-term overload capacity: 140°C (2 hours); thermal shrinkage <0.5%.

Oil Resistance

Swelling rate <3% and oil absorption <5% after immersion in mineral oil, preventing deformation-induced insulation failure.

Environmental Adaptability

Silane-treated versions resist moisture (weight gain <2% at 95% humidity); specialized coatings prevent corona erosion.

Application Scenarios

Oil-Immersed Transformers

Interlayer Winding Support: Typical spacing 30-50 mm, thickness 2-6 mm, forming axial oil ducts (3-8 mm wide) to improve heat dissipation by 15%-30%.

Winding End Fixation: L-shaped spacer assemblies with preload design to prevent axial displacement.

Core Insulation Isolation: Spacer groups (10-20 mm thick) withstand core vibration acceleration >5g.

Dry-Type Transformers

Use epoxy-impregnated pressboard with arc-resistant coatings (e.g., Al₂O₃), suitable for Class F/H insulation systems.

Specialty Transformers

Mica-reinforced composite pressboard in furnace transformers (temperature resistance up to 180°C); high-density pressboard (≥1.25 g/cm³) in converter transformers to withstand harmonic vibrations.

High-Voltage Reactors

Multi-layer staggered spacer structures enable segmented oil gap designs for optimized electric field distribution.

Technical Specifications for Selection

Material Selection

Standard voltage (≤110 kV): T4 pressboard (density 1.15 g/cm³);

Ultra-high voltage (≥220 kV): High-density pressboard (≥1.25 g/cm³) or Nomex® composite boards (220°C rated).

Dimensional Design

Thickness tolerance ±0.05 mm, meeting: thickness ≥0.1×radial winding dimension and ≥3 mm;

Width based on oil duct design: width ≥0.6×oil flow velocity (m/s)×spacer spacing (mm).

Electrical Parameter Matching

Operating field strength ≤3 kV/mm (oil gap), spacer field strength ≤8 kV/mm;

Creepage distance: ≥1.5×rated voltage (kV) in mm.

Mechanical Verification

Compression deformation test: Residual deformation <2% after 1.5×design pressure (typically 50-100 N/mm²);

Vibration test: Passes 20-2000 Hz sweep with amplitude ≤50 μm.

Special Environment Adaptation

High altitude: Increase spacer height by 10% per 1000 m elevation;

Humid regions: Use anti-mold pressboard with 2% boric acid.

Quality Control Highlights

Raw Material Testing

Ash content ≤0.8%, moisture content 5%±1% (per GB/T 1927 standard).

Process Control

Hot pressing: 160-180°C under 2-4 MPa pressure for 30-60 minutes;

Edge chamfering precision: R-angle tolerance ±0.1 mm (laser cutting).

Testing Requirements

Partial discharge <5 pC (at 1.5Ur);

Post-oil-resistance test (100°C/48h): Tensile strength retention >90%.

Typical Technical Parameters

| Parameter | Standard Type | Ultra-HV Type | High-Temp Type |

|---|---|---|---|

| Density | 1.15 g/cm³ | 1.28 g/cm³ | 1.18 g/cm³ + coating |

| Dielectric Strength | 12 kV/mm | 15 kV/mm | 10 kV/mm |

| Heat Deflection Temp | 130°C | 150°C | 200°C |

| Typical Dimensions | 3×20×1200 mm | 5×30×1500 mm | 4×25×1000 mm |

| Voltage Application | 35-110 kV | 220-500 kV | Class H Dry-Type |

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 65 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first. Products are exported to Europe, America, Southeast Asia and other countries and regions.

If you need to know more about phenolic resin sheets and other insulation materials product information and quotations,

please contact us, we can mail you samples for your testing

Welcome to visit our factory for guidance.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations