The "yarn count" in the phenolic cotton cloth tube (also known as phenolic cloth tube, phenol cotton tube) refers to ...

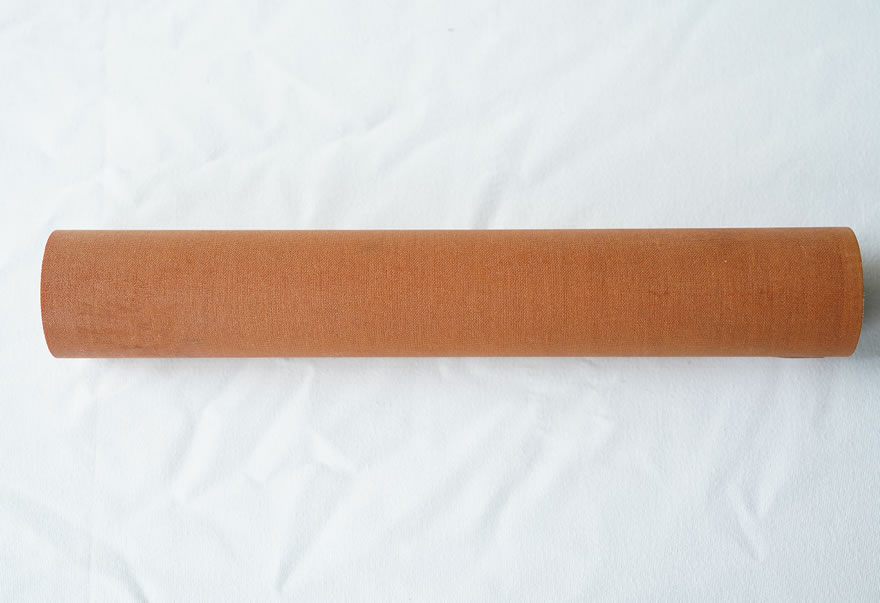

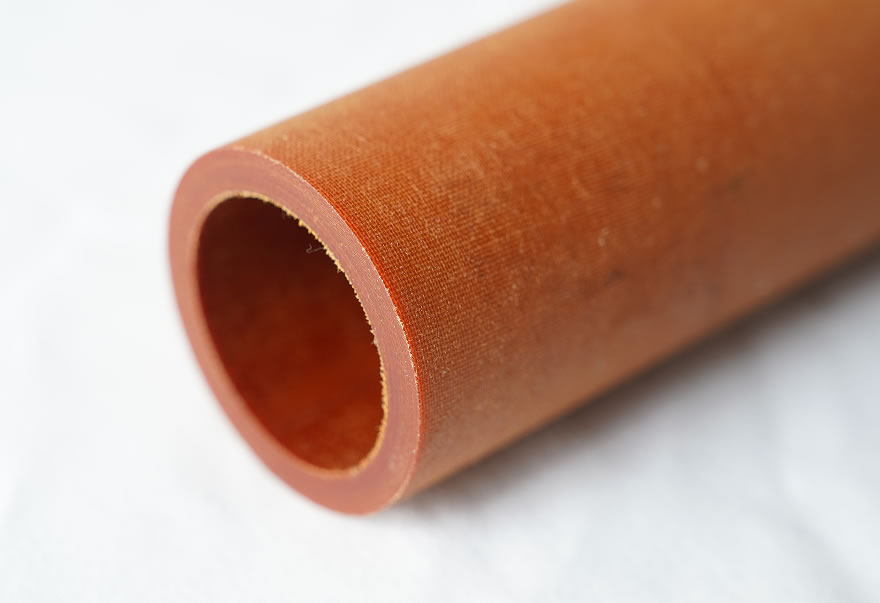

The “yarn count” in the phenolic cotton cloth tube (also known as phenolic cloth tube, phenol cotton tube) refers to the thickness of the yarn in the cotton cloth used, that is, the “yarn count”. This is an indicator to measure the fineness of the cotton cloth, and has a significant impact on the performance, appearance, cost, etc. of the final phenolic cotton cloth tube.

The following are the main differences between different yarn counts:

| Yarn Count | Features | Application Traits |

| 21s (20~24s) | Coarse yarn, high strength, low cost | Rough surface, suitable for structural parts requiring high mechanical strength |

| 28~32s | Balanced precision and strength | Good balance between mechanical and insulation properties, commonly used standard type |

| 40s and above | Fine yarn, smooth surface, better resin penetration | Excellent electrical performance, ideal for high-precision electrical parts |

Based on Performance Requirements:

| Application Needs | Recommended Yarn Count | Reason |

| High mechanical strength (e.g., motor shaft sleeves, impact-resistant parts) | Around 21s | Coarser yarn provides greater strength |

| High electrical insulation (e.g., high-voltage insulation tubes) | 32s or 40s | Finer yarn enables more uniform resin impregnation and better electrical properties |

| High surface smoothness (e.g., visible parts, precision electronic structures) | ≥40s | Fine fabric texture with minimal yarn marks |

| Cost-sensitive projects | 21s–28s | More economical while meeting basic requirements |

| Custom complex sizes or heavy post-processing | 28s–32s | Better processability and stable performance |

Based on Industry and Application Scenario:

| Industry | Recommended Yarn Count | Reason |

| Motor/Transformer Manufacturing | 28s–32s | Balances insulation and structural performance |

| Machinery/Structural Parts | Around 21s | Emphasizes strength and cost-efficiency |

| High-end Electronics/Rail Transit Equipment | ≥40s | Demands high precision and insulation |

| Item | Low Yarn Count (e.g., 21s) | High Yarn Count (e.g., 32s, 40s) |

| Yarn Thickness | Coarse | Fine |

| Fabric Surface Appearance | Rough, pronounced texture | Smooth, fine, and flat |

| Mechanical Strength | Higher (due to thicker yarn) | Lower (but more uniform) |

| Wear Resistance | Strong | Slightly weaker |

| Resin Impregnation Capability | Better penetration | Slower penetration |

| Insulation Performance | Slightly lower | Slightly higher |

| Cost | Lower | Higher |

| Suitable Applications | High strength required, appearance not critical | High insulation and surface quality required |

Higher yarn counts mean higher cost: Both material cost and processing difficulty increase with finer yarns.

Higher is not always better: Excessively fine yarn may reduce strength and increase unnecessary cost.

Check supplier specifications: Yarn types may vary between manufacturers; it’s best to evaluate actual samples.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778