G10 insulation gasket usage scenarios

G10 fiberglass sheet is a high-performance insulation material. It is widely used in the following scenarios due to i...

G10 fiberglass sheet is a high-performance insulation material. It is widely used in the following scenarios due to its high strength, high temperature resistance, corrosion resistance and excellent insulation performance:

G10 insulation gasket usage scenarios

High-voltage electrical equipment

Transformers, switch cabinets, bus ducts: as insulating partitions or gaskets to isolate high-voltage conductors and prevent arc discharge.

Power electronic equipment: used for insulation support of high-voltage components such as IGBT modules and capacitors.

Machinery and industrial equipment

Motors and pump bodies: as wear-resistant and insulating pads in high temperature or vibration environments.

Automation equipment: prevent electrostatic interference and protect precision circuits (such as robot control boards).

New energy and automobiles

Electric vehicle battery packs: isolate battery modules to prevent short circuits; support high-voltage connectors.

Charging piles: high-voltage insulation components used inside DC fast charging piles.

Aerospace and military industry

UAVs, satellites: lightweight structural parts that meet insulation and vibration requirements at the same time.

Radar equipment: insulation support in high-frequency circuits to reduce signal loss.

Laboratory and Chemical Industry

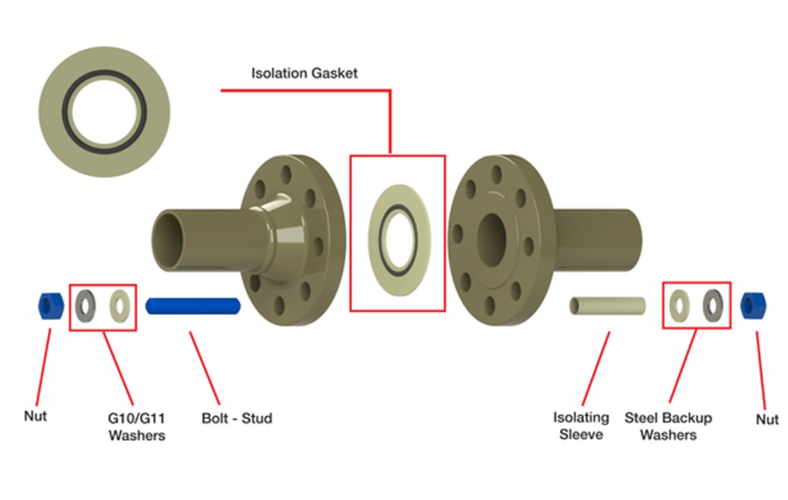

Corrosion-resistant environment: As an insulating flange gasket for reactors and pipelines, it can withstand weak acids and weak alkalis.

High-temperature experimental equipment: Short-term temperature resistance can reach 150°C, used for heat insulation and insulation.

Key steps in selection

1.Clarify the working conditions

Temperature: Conventional operating temperature (-50°C~120°C). If it exceeds, high-temperature resistant materials (such as G11, PEEK) must be selected.

Voltage level: Calculate the required thickness based on the dielectric strength (typical value 20kV/mm) (for example, 10kV voltage requires at least 0.5mm thickness).

Mechanical load: Compressive strength ≥500MPa, high load scenarios require increased thickness or metal lining.

2.Chemical environment matching

Resistant to weak acids and weak alkalis, but long-term contact with strong acids (such as concentrated sulfuric acid), strong alkalis or organic solvents requires PVDF or PTFE.

3.Size and processing requirements

Thickness selection: Common 1~50mm, thin gaskets (1~3mm) are used for light insulation, and thick gaskets (>6mm) are used for high voltage or high load.

Tolerance control: Precision equipment requires ±0.1mm tolerance, and ±0.5mm is sufficient for ordinary scenes.

Shape complexity: Simple shapes can be cut by laser, and complex structures require CNC processing (higher cost).

4.Special performance requirements

Flame retardancy: Choose flame retardant G10 that meets UL 94 V-0 standard.

Moisture resistance: In humid environments, the surface needs to be coated with a moisture-proof coating (such as silicone), or G11 with a lower moisture absorption rate should be used instead.

5.Certification and cost balance

Prioritize materials that meet RoHS and REACH environmental standards.

Select standard G10 (high cost-effectiveness) for conventional scenarios, and select modified G10 or composite materials for extreme environments.

Selection considerations

Avoid long-term high temperature: Exceeding 120°C will cause epoxy resin aging and reduced insulation performance.

Installation stress control: Uneven tightening will cause local cracking, and it is recommended to use a torque wrench.

Surface treatment: The surface needs to be polished in high-voltage scenarios to reduce the risk of corona discharge.

Alternatives: Higher temperature resistance: G11 (resistant to 180°C), PEEK (resistant to 260°C).

Higher corrosion resistance: PTFE, PVDF.

Summary

The selection of G10 insulating gaskets needs to comprehensively consider the four core parameters of electrical performance, mechanical strength, temperature, and chemical environment, and adjust the thickness and processing technology according to the specific scenario. If the working conditions are complex, it is recommended to conduct small sample tests (such as pressure resistance and temperature rise experiments) first to ensure long-term reliability.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations