Diphenyl ether fiberglass cloth laminated tube is made of fiberglass cloth impregnated with diphenyl ether. Its insulation class is H class and mainly used as insulating structural spares in electrical equipment.

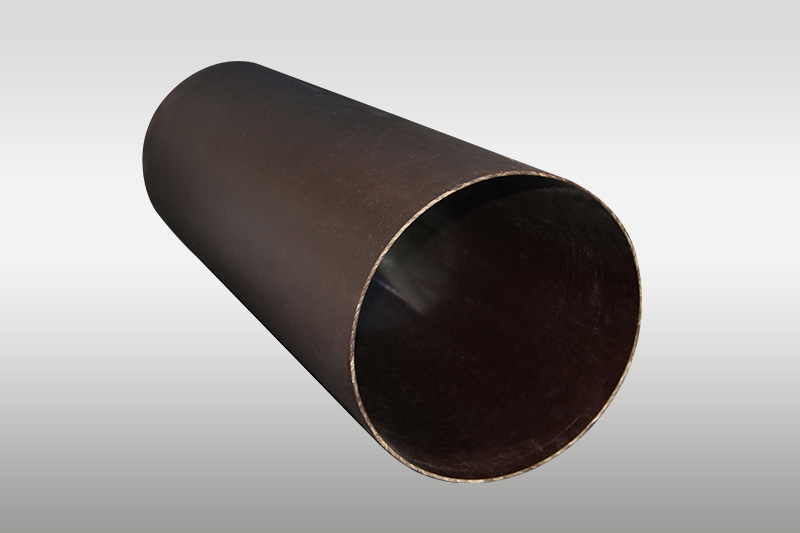

Diphenyl ether fiberglass cloth laminated tube is tube-like laminated products, which is manufactured by fiberglass cloth soaked in diphenyl ether resin, and then rolled, backed and cured under heat and hot pressing with good electrical property and strong mechanical processing performance. The insulation class is H class and the main color is dark brown.

It is suitable for insulating structural spares in electrical equipment, and can be processed into coil insulation cylinder of dry-type transformer and insulation terminal coil of transformer.

Diphenyl ether fiberglass cloth laminated tube, produced by ZTelec Group using Diphenyl ether resin as raw material, can be mass-produced with advanced production equipment and full automatic production line.

This product has the advantages of reliable quality, uniform color and neat cutting ends with strict manufacturing technology.

ZTelec Group is equipped with advanced ventilation facilities and dust-removing equipment to keep the products dry and clean.

The mechanical and electrical properties of products are superior to the similar one of other companies.

Its quality is recognized by domestic and foreign large enterprises such as Lens Technology in China and Schneider Electric and sold overseas such as European and American areas.

Executive Standard:JB-T3172-1999(3520) GB-T5132-2009 IEC61212-2006

| Number | Item | Unit | Value |

| 1 | Density | g/cm3 | 1.7-1.8 |

| 2 |

Flexural Strength at Perpendicular Lamination (Under Normal) |

MPa | ≥80 |

| 3 | Axial Compressive Strength | MPa | ≥70 |

| 4 |

Breakdown Voltage at Parallel Lamination (Transformer Oil at 90℃) |

Kv | ≥25 |

| 5 |

Dielectric Strength at Perpendicular Lamination (Transformer Oil at 90℃) |

KV/mm | ≥6-14 |

| 6 | Dielectric Loss Factor(50Hz) | - | ≤0.03 |

| 7 | Water Absorption (3mm) | % | ≤1 |

| 8 | Thermal Index | - | 180 |

| Name | Unit | Value |

| Minimum Wall Thickness | mm | 2 |

| Maximum Wall Thickness | mm | 200 |

| Minimum Bore Size | mm | 6 |

| Maximum Bore Size | mm | 1200 |

| Length | mm | 1000-1200 |

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it. Email: info@ztelecgroup.com Whatsapp: +8615716749170